Keen Compressed Gas of Wilmington, Delaware, is proudly celebrating 100 years of service to its customers. Stanley Keen established the business in 1919 with the goal to be a company whose associates work hard to achieve total customer satisfaction in the delivery of its products and services. “Delivering on that promise,” says Bryan Keen, the company’s third-generation president, “is how we have achieved a century of success.”

In the Beginning

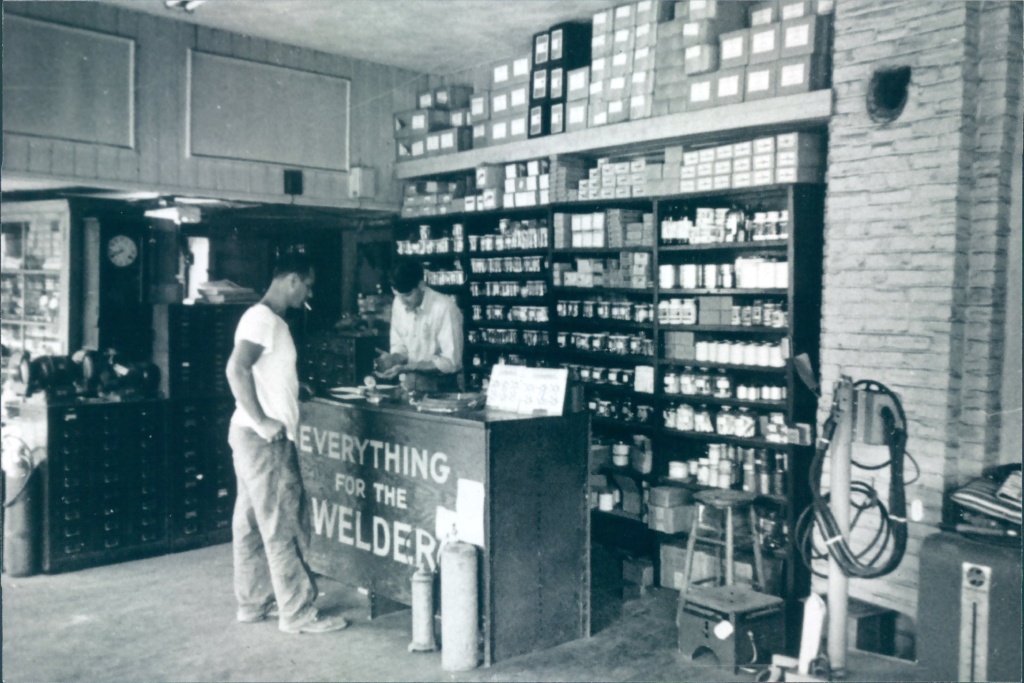

One hundred years ago, the welding and gases business as we know it today barely existed and the industries from which it emerged were just getting started. Having served his country during World War I, Stanley Keen was interested in founding a business in his hometown of Wilmington, Delaware. With the help of his father, he opened Keen Auto Parts in 1919. At the time, the U.S. automotive industry was growing fast, with more than 90% of all cars in the world manufactured here. Keen provided car parts and equipment, including the small acetylene cylinders commonly used for headlights at that time.

Keen’s business grew steadily along with the emergent auto market, and by 1925 Keen had expanded its original facility. As welding repair work took on greater significance in the business, the company became more involved with gases. By 1928, Keen was selling both acetylene and oxygen cylinders.

Selling More Gas

The company’s transition from servicing mostly the automotive market to the larger industrial gas business, really heated up in the 1940s. Keen added propane to its business in 1943. At that time, propane was mostly sold into the home heating and home use markets.

During this period, Keen also began supplying gases to the growing manufacturing base in the Wilmington area, including auto manufacturers. Says Bryan, “While most of those manufacturers are gone today, Keen maintains a strong customer base of small and mid-sized fabricators which are still prevalent in our region.”

By 1946, the gases side of the business was so significant that the company incorporated under a new name, Keen Compressed Gas. When an industrial accident caused irreparable damage to the company’s only facility in 1952, Keen successfully managed to operate out of local garages until its new building was finished being constructed in 1953. That facility had added capacity and the company continued to flourish.

A More Aggressive Approach

Stanley Keen was a skilled businessman. “He was able to support a family of 13 children by building this enterprise from the ground up,” Bryan says. Like many of his generation who had lived through the challenges of the Great Depression, however, Stanley took a conservative approach to business, working out of only one main facility during his tenure.

In 1965, J. Merrill Keen, the youngest of Stanley’s 13 children, took over as president. He had been part of the family business since 1960 and, recognizing the company’s potential for growth, adopted a more aggressive approach to market expansion.

In 1969 he spearheaded the acquisition of Anchor Welding Supply and in one bold stroke tripled the size of the company. As an Airco distributor, Anchor Welding was fully set up in the industrial gas and welding business and Keen began selling a much wider range of gases and hardgoods. As Bryan explained, this was a big turning point for the company: “It [Anchor acquisition] marked the beginning of the gas distribution business for Keen. Merrill was able to get a lot of guidance on how to run the gas business from this new relationship with Airco.”

Keen has remained with the same gas supplier for 50 years, though their names have changed. “Our original supplier, Airco, was sold to BOC, which became Linde,” Bryan says. “Recently, the Linde plant that provides Keen’s gases was sold to Messer, which delivers to us today.”

A Turning Point

Merrill continued to expand the business. In 1972, the company purchased its New Castle Avenue property just outside of Wilmington and built a fill plant. Keen’s filling operations are still centered at that site today.

Jon Keen, customer service manager for New Castle, explained the transition to fill. “Keen had been struggling with supply issues and customer complaints,” he says. “When our plant was built, Airco provided the proper training and education we needed to run it. This turned out to be a big turning point and the beginning of a totally different approach to running the business.”

By filling its own cylinders, Keen gained greater control of its distribution process and the ability to grow its customer base. A period of branch expansion followed and, in the late 1970s, Keen opened two additional stores, one in Dover, Delaware, and one in Millville, New Jersey.

This was followed by a further build-out of the business in the 1980s and ‘90s, when Keen expanded into neighboring Maryland and Pennsylvania, adding six more branch locations. It also established its medical and specialty gas divisions during this period and introduced welder training schools.

Specialty Gases

Keen built a specialty gas lab in 1984 in order to be able to supply its own gases to its growing spec gas customer base. The company started with making High Purity (HP) gases and today makes a wide range of specialty gas blends and mixes.

“The spec gas plant gave us greater control of our assets and enabled us to provide better customer service,” says Bryan. “We continue to increase our share of this market and are in the process of building a brand-new specialty gas lab with state-of-the-art capabilities.”

The timing of introducing spec gas capacity was fortuitous. The departure of local manufacturers from the region in the 1980s caused Keen’s industrial business to fall off. Its specialty gas capabilities enabled the company to grow its customer base in the emerging R&D and life sciences markets.

“Today, Keen has a special division, Keen Cryo, which has a salesman, four dedicated trucks and two service technicians that focus on the cryogenic needs of the biotech and life sciences markets,” says Jon.

The Third Generation Takes Charge

When Bryan Keen, Merrill’s son, was named president in 2000, he took command of a business that had undergone tremendous expansion since its founding 80 years earlier. As he saw it, “The many branch expansions that took place under my father’s presidency were opportunities to buy out competitors and pick up new business in order to position Keen to better serve its ever-expanding customer base.”

Bryan has embraced that philosophy and continues to take steps to further strengthen Keen’s position in what is an increasingly competitive market. In 2001, the company purchased its first nitrogen microbulk delivery vehicle, with the emergent biotech and life sciences market in mind. Those markets were in their infancy at the time and getting into microbulk was a proactive, as opposed to reactive, business decision. “We wanted to stay ahead of the market,” says Bryan.

The company also realized that biotech required a different kind of selling and reorganized its sales efforts accordingly. Today, bulk, microbulk and cryogenic liquid cylinders are a significant part of the business and a key element in the company’s growth strategy.

Growth through Diversity

Keen has grown from a single location in Wilmington, Delaware, into a major regional distributor with 14 branch locations that supply gases and equipment to a four state area. And biotech isn’t the only market Keen has had to pay attention to. Today, the company has a 50/50 hardgoods to gas mix of business and serves a wide range of markets.

“We still sell a lot of traditional welding machines, electrodes, filler metals and safety equipment,” says Bryan. “On the gas side we continue to supply large welding and fabrication concerns and power plants, as well as hospitals, universities, medical facilities, labs and the life science market. We pride ourselves in having a foothold in many markets, which helps us weather recessionary trends.”

Staffing for the Future

With a group of third-generation family members on board as well as many managers with long-term experience, Keen has a solid team in place to lead the company into the next century. Managers like Vice President of Finance Dave Haas, have been with the company for more than 40 years, as has the company’s Vice President of Operations Steve Shupe.

In fact, Kim Keen, administrative manager, reports that Keen has 27 employees that have been with the company for more than 25 years. Kim recognizes the benefits of having long-standing employees and also the challenges involved in replacing them. She explained how the company is approaching this dilemma.

“Five years ago, we began identifying retirees well in advance of their departure so that we could bring in the right people to replace them,” says Kim. “We look closely at the functions of our long-time employees, who are often doing the jobs of three people, and redefine job descriptions as needed. We also start new employees early to make sure they are a good fit. This system is working well for us.”

What’s Ahead

While the Keens are proud to share their 100-year history, it is really the next century of business they are most excited to talk about.

In 2018, Keen Compressed Gas began construction on a new automated $6 million fill plant, which includes capabilities for both industrial and specialty gases. The CryoVation plant is fully automated and palletized and the new building sits on the same property as its existing fill plant. Importantly, the process of getting the plant’s ISO certification is underway.

“We see this is a major investment in our future on the gas side. It will allow us to better compete with the majors,” says Bryan. “Computer driven and gravimetric, the new plant enables us to produce more accurate mixes, including our own medical CO2, blood gas mixes, some CO mixes, flammable gases and other specialty mixes, many of which we now buy from another producer.”

Keen has a growth annual rate of about 4-5% per year.

“I would describe our approach to growth as opportunistic” says Bryan. “When an opportunity arises, we take advantage of it, whether it is to add talent, enter a new market share or make an acquisition. We plan to continue on this path and have identified new markets and geographies with the greatest potential, particularly those in which specialty and cryogenic gases are in demand.”

The Celebrations Begin

Keen is, first and foremost, a people-oriented company. Says Kim, “All the steps we take are done in the context of treating our people and our customers right. That remains our central mission. Our business is all about establishing long-term personal relationships with the people with whom we interact – be they employees, customers, or vendors.”

To thank the people that have enabled the company to enjoy 100 prosperous years, Keen is planning a series of events. On March 30, they kicked off the celebration with an anniversary reception and dinner, attended by more than 150 people. Guests included employees, spouses and friends of the company.

“This was a great way to begin our thank yous to the people who helped get us to this important anniversary,” says Bryan.

Next up is a series of customer appreciation days, which Keen will host at each of its branch locations throughout the spring and summer. To show their gratitude to both customers and vendors, there will be plenty of good food, live demonstrations and promotional deals to be enjoyed by all.

Wrapping up the centennial celebrations this fall will be a three-day event at company headquarters. Keen intends to roll out the red carpet, providing guests with culinary delights, enlightening product demonstrations and promotional deals. Most importantly, this will be an opportunity for people to tour Keen’s new state-of-the-art fill plant.

“It will be a great chance for customers to see and learn about our new capabilities firsthand,” says Jon.

A People Business

It’s difficult to summarize 100 years of hard work in just a few pages, but a new $6 million fill plant certainly is a remarkable testimony to just how much this family-led company has grown since its days selling automotive parts.

“With this plant,” concluded Bryan, “we gain more control of our own destiny. We see the cylinder gas side of the business remaining relationship-based and served by those that can offer the best total value. Response time is very important to customers and our new technology will enable us to serve them better. We remain a people business and will continue to build our company with talented individuals and acquisitions that support Keen’s mission to be the premier welding and gases supplier in our region.”

Agnes H. Baker is a freelance writer and editor with 20 years of experience covering the industrial, medical and specialty gas industry. Based in Massachusetts, she is at: agnes.h.baker@gmail.com.