Professionalism, Productiveness, and Safety

How DeLille Oxygen’s three-tiered system has allowed the distributor to thrive for nearly a century.

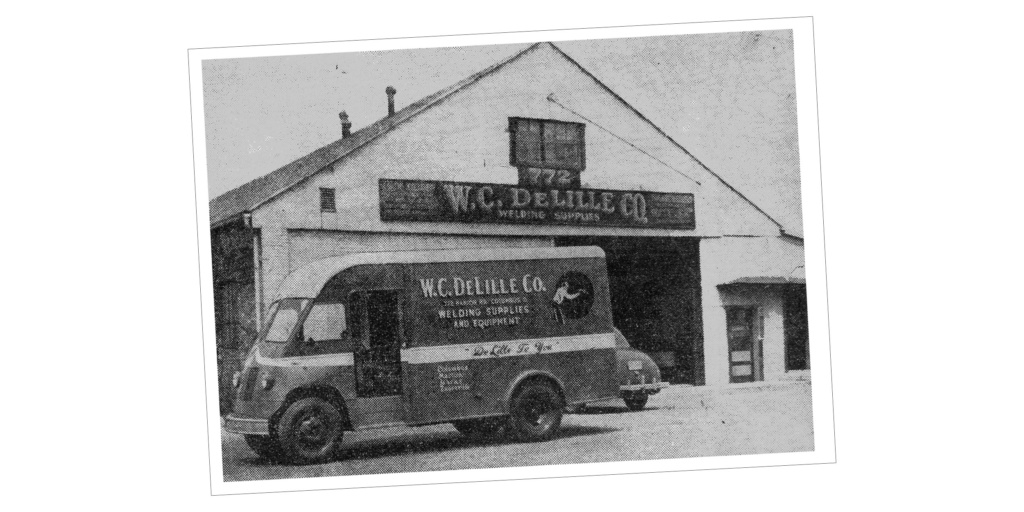

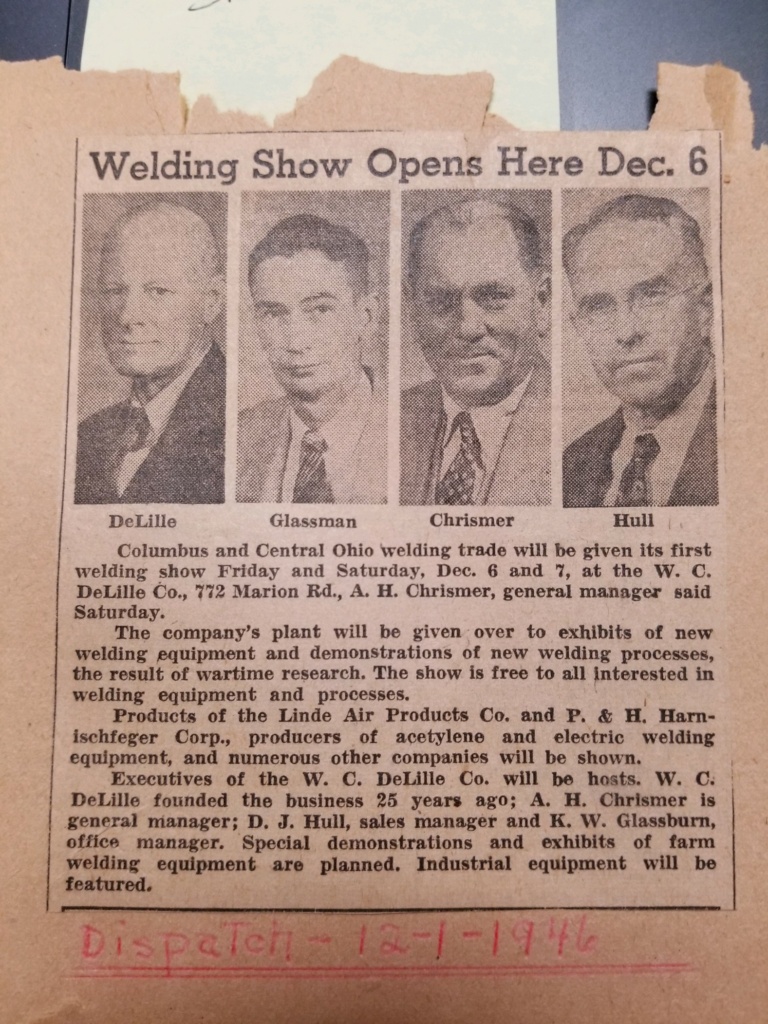

DeLille Oxygen Company was founded in 1924 by W.C. DeLille. Originally, DeLille supplied coal and ice. However, shortly after its founding, DeLille shifted its focus to the welding supply industry, becoming a supplier of gases and hardgoods to the industry the company still serves nearly a century later.

As the company found success in the gases and welding industry, W.C. DeLille continued to grow the company’s footprint. He added multiple locations throughout Ohio and continued to service different areas of the industry. In 1950, DeLille built its first Oxygen plant to begin to fill its own cylinders, marking it as a truly independent distributor, which it continues to operate as today. At that time, high-pressure cylinder filling was rare for independents. In what would become a hallmark of the company, DeLille saw the opportunity to react quickly to customer demands and seized it.

Eventually, W.C. DeLille sold the business to the Smith family, who continued to grow the welding supply business, eschewing the coal and ice business completely. Finally, in 1963, the business was sold to J.R. Smith (no relation to the previous owners), whose family still owns the business today. J.R.’s son, Tom Smith serves as CEO, with Josh Weinmann serving as President.

Growing into a Turnkey Distributor

The same year that J.R. purchased the business, DeLille made one of the most consequential decisions in the history of the company. The company had a Rexarc Acetylene generating plant built that produced Acetylene from Carbide.

“That was when the entire idea of gas manufacturing and generation really took effect within DeLille,” says Weinmann. “That started us on the path of making our own gases and that has really pushed our growth through all of the years. We were one of the first independents that started doing specialty gases.”

While gas manufacturing would be the primary growth driver for DeLille, the company continued to operate as a true turnkey distributor, servicing both gas and hardgoods customers. In 1987, the company started its own equipment repair division. At that same time, DeLille started an equipment rental division in an effort to provide welding and cutting machines to its customers. These divisions continue to thrive today, expanding from being a certified repair facility not only for Lincoln and Miller, but also for ESAB, Hypertherm, and many other equipment manufacturers.

Then, in 1990, DeLille started its own Specialty Gas division.

“Manufacturing acetylene has been one of our main drivers,” says Weinmann. “In the early 90s, when most independents weren’t doing spec gas, we had our own specialty gas lab. We’ve grown that part of the business. Then, obviously, we started an electrolysis plant, making our own high purity hydrogen and oxygen. And then, finally, we got into bulk. That has been our big growth driver for the last 15-20 years.”

The company got into the bulk business in 2010, purchasing microbulk trucks to serve its bulk customers to its customer service standards.

“Our growth in bulk was definitely customer-driven,” says Weinmann. “Customers wanted to make sure that if they were buying from us, it was our trucks and our people making the deliveries. They didn’t want to go bulk with us if we weren’t the actual ones who were managing their bulk tanks or telemetry.”

In 2017, the company expanded beyond microbulk and into bulk when they purchased bulk tankers to be capable of delivering to bulk customers in the best way possible. The company’s aim is to supply any capacity a customer would ever need and the bulk division, alongside the cylinder division, ensures that.

In 2014, DeLille started manufacturing high purity oxygen and hydrogen at its Columbus location. The company has continued to produce these high grades of ultra-high purity oxygen and scientific grade hydrogen as customer needs expand. The company is able to offer them in bulk, as well.

The company is also in the process of building two carbon monoxide plants to continue its growth in specialty gas.

“A customer needed some carbon monoxide, and we had that background in gas manufacturing, particularly electrolysis, so it was something we were comfortable with doing,” says Weinmann. “It was very customer-driven, and we do see some industry void, especially in our area, for carbon monoxide.”

Acquisition of Nyeco

Since its inception, DeLille has made its bones in identifying areas of need in the industry and growing organically to fill them. However, in 2016, the company made its first ever acquisition, acquiring Nyeco Gas in order to expand its service footprint into the northern Ohio region.

“That was the first acquisition we had ever done and we’re really happy with how it has been going,” says Weinmann. “It’s really been successful for growth. It did have its challenges, blending their culture into ours and vice versa, but we’re at a point now where it’s really going great and we’re really happy with the way it turned out. It really taught us that acquisitions can be a good thing and may be something we would consider again moving forward.”

Company Culture

While DeLille has built itself into a true one-stop-shop for both the hardgoods and gas industry, it wouldn’t have been able to grow to the heights it has achieved without a staff in place that fully buys into the culture and the vision.

The company is built on three fundamental tenets for growth. Professionalism, Productiveness and Safety. The company strives to make every single interaction with customers and employees the best experience possible, something it attributes to the three-tiered environment it has built.

“We evaluate everything we do, both internally and externally, to verify it is the best practice in order to achieve those three environments,” says Weinmann. “It’s something we demand of every employee at DeLille. And it really creates a great working environment and particularly a great learning environment for our employees.”

From the time they are hired, every DeLille employee is taught different positions and facets of the company.

“They’re taught constantly,” Weinmann says. “We can back each other up. That really helps our customers. Our trained and skilled employees can go out and see our customers every day. It’s a benefit to the employees because it helps them grow within the company. They’re taught by other employees and management and we’re all held to the same standard of being productive, professional, and, all the while, remaining safe while we do everything that we do.”

He continues, “We have a three-tiered system. And if one of those tiers is missing, it won’t work. They must work together, in unison, to be successful. It’s something we preach constantly at all levels of the company.”

Like all GAWDA members, recruiting is one of the biggest challenges facing DeLille. Finding skilled employees who will buy all the way into the company’s culture is something that the company takes very seriously.

“It’s difficult. It’s probably one of the biggest challenges that we have faced is recruiting and getting good talent,” says Weinmann. “When we successfully find a person, we give them that broad training to acclimate them to every area of the company. And we keep them involved. We don’t just send them off to a certain plant or position. We let them know that their input is important. We welcome it on every project that we’re doing. Even if it doesn’t really fit their job title. It keeps them involved and intrigued with what we’re doing. We let them participate in everything we do. We’ve found that when an employee is hired, if they are still with us after three months, they tend to be here forever.”

Today, the company has 82 employees across its 10 branches.

Safety

As one of the three pillars of DeLille’s culture, safety has always played an integral role in the company’s growth. In 2020, however, it proved more important than ever. Having a culture that is so safety-focused allowed DeLille to spring into action at the outset of the COVID-19 pandemic and put a plan in place to keep its employees and customers as safe as possible. Its culture of professionalism and productiveness ensured that employees could work remotely without the need for micromanagement or fear of a lack of productivity.

“We implemented policies and guidelines very quickly,” Weinmann says. “They were all based on the guidance of the state of Ohio and the CDC. Obviously, we mandated the use of face masks and installed safety dividers for counters. We limited work areas as best we could. Did temperature checks. We even started, initially, steaming cylinders because nobody really knew how long COVID stayed on surfaces. We didn’t want to use any harsh chemicals on the cylinders that could get back into the tanks. So, we used steam. We did all of those right out of the gate to help protect our employees and customers.”

One of the biggest things the pandemic brought to light was just how face-to-face oriented the company was.

“We had always been a face-to-face business,” says Weinmann. “So, it was really a step back when we really couldn’t do that anymore. And we still can’t do that all that well. So, we had to learn how to use online meetings and digital platforms. And it has really helped us grow our company, in a way.”

For a business as geared toward in-person interaction as DeLille was, this could have been a jarring and disruptive change. But because of the culture it has built over 95+ years, employees were able to take it in stride and even become more efficient.

“We had a lot of people working remotely,” says Weinmann. “And we really didn’t see any issues. Everybody stayed productive. They were available whenever we needed them. I credit that, a lot, to our people. We didn’t have to do audits or anything like that to make sure people were working. They just were. And it certainly became a benefit to those employees, and they learned quickly that a lot of them wanted to continue to work remotely, even after the pandemic. It has actually made us more productive. We can achieve a lot more a lot faster by doing online meetings and stuff like that instead of trying to get everybody in one meeting. So, we get a lot more done.”

Turning 100

DeLille will mark its 100th anniversary in 2024, a milestone that the company is excited about, but certainly not one that will cause it to be complacent.

“To us, you’re only as good as your last interaction with a customer,” Weinmann says. “What has made us successful has been our ability to provide solutions to our customers and be innovative. We can’t rest on our laurels and be satisfied with the fact that we’ve been doing this for 100 years. We have to keep progressing and transforming and become even better for the next 100 years.”

As its experiences with COVID taught the company, one area that will be of paramount importance as it begins its journey to 200 will be its web presence. Weinmann joined the business 23 years ago and has had a front row seat to see how the growth of the Internet has impacted both DeLille and the industry as a whole.

“I remember, when I first got into sales, I had a customer that demanded email. And it was almost taboo that I was emailing a customer back and forth. Emails were just considered to be impersonal. Now, everybody emails,” Weinmann says. “It’s just something that has taken off. And now it’s something that is translating into other areas of the business. Ecommerce and online stores, things like that. We’re starting to go down that path. And it’s just so important to keep your website updated and relevant because the customer base has changed so much.”

He continues, “Before a customer even walks into your store, they have already checked you out online. If your website is not updated, if it’s not mobile friendly, if it’s not easy to navigate or doesn’t give enough information or context, you’ve lost that customer before you even had a chance to speak with them. Having a strong online presence is vital to the new customer base. We always like doing business face-to-face but a lot of our customers don’t want that anymore. You have to communicate with them the way they want to be communicated with.”

As the company prepares to turn 100, it does so as an innovative, turnkey independent distributor, perfectly positioned to make the next 100 even better than the first.