Congratulations to all GAWDA Members celebrating anniversaries in 2024

The past several years have represented a dramatic shift in the gases and welding industry. We’ve seen the industry get leaner, as M&A activity continues to shrink the industry, while the internet, and the rise of AI and other technology makes the entire world smaller and more connected. But, in a larger sense, the fundamentals of the business remain the same. This industry remains a relationship business. While the X’s and O’s may look different today than they did 100 years ago, the overall playbook remains very similar. And there’s a reason that GAWDA members continue to persevere year after year, generation after generation. While technology continues to advance, the culture and the infrastructure remain the same. GAWDA members are built on solid bedrock principles, which allow them to continue to thrive, no matter the technology. Congratulations to all those GAWDA members who are celebrating anniversaries in 2024! And if you have a milestone anniversary coming up in 2025 and would like to be featured in this issue next year, please reach out today at [email protected].

Jump to Section:

GAWDA Members Celebrate Milestone Anniversaries in 2024: 100-225 Years

GAWDA Members Celebrate Milestone Anniversaries in 2024: 60-85 Years

GAWDA Members Celebrate Milestone Anniversaries in 2024: 30-55 Years

GAWDA Members Celebrate Milestone Anniversaries in 2024: 5-25 Years

85 Years

Huber Supply Company

Distributor

A boat’s engine problems laid the unlikely foundation of Huber Supply Company. Elmer Smith was on a boat trip on Lake Erie one weekend when his boat developed engine trouble. He was stranded at a boat works outside of Port Clinton, Ohio, which wouldn’t be open until the following Monday. However, Nelson Schmidt, who was the son of the owner of the boat shop, worked all day and night to help get Smith’s boat up and running. Elmer was so impressed that he told Nelson that if he was ever in Minneapolis looking for work as a welder to look him up. As fate would have it, Schmidt did just that.

Smith hired Schmidt as a salesperson when Schmidt moved up to Minneapolis. Fate struck again when Schmidt found a room at George Huber’s grandmother’s house just blocks away from the Smith Equipment Plant. George and Nelson became quick friends and began to talk of starting their own oxygen-acetylene supply route together.

In the summer of 1939, George and Nelson began securing oxygen and acetylene and lining up customers for a route starting in southern Minnesota.

After a route early in the company’s history, George stopped to fuel his truck and found out the news that Nelson had been killed in a car accident. Nelson was a major supporter of the welding business. He bank-rolled the project and kicked in $25 per week to keep food on the table at George’s house. When George’s folks came to the funeral, George had to borrow money from his dad to keep the new business going. After his first month in business, George had cleared $50. Though he lost a friend and business partner, he was very happy with the business’s success.

Fast-forward 85 years and Huber has continued that legacy of considering the customer as a partner.

“We put the customer first,” says Cal Huber, Vice President of Operations at Huber Supply Company. “When we are looking to add new lines or services we ask our customers what they need from us. For example, there was a need from our customers for reliable delivery of propane forklift cylinders. This was a new market for us in 2019 which has grown immensely. We now sell more forklift propane cylinders than any other cylinder. It all came from asking our customers their pain points and trying to find a solution for that pain point.”

85 years since fate struck in Lake Erie, Huber Supply now has three locations, including an online website, weldingoutfitter.com, and 29 employees. Says Huber, “Our employees are our biggest asset. Without every team member that walked through the Huber Supply doors, we wouldn’t be where we are today.”

The company is also a part of the Absolute Air consortium of businesses.

“That has helped us have consistency and reliability for all of our bulk oxygen, bulk nitrogen, and even bulk argon customers,” Huber says.

He concludes, “Huber Supply is a fun and reliable business to work for. We want our employees to have a reason to retire at Huber Supply. We want them to feel the satisfaction of being able to complete their job from start to finish. We promote everyone at Huber Supply Company to offer ideas and suggestions on how we can do things more efficiently and better for the customer. As owners we try to track all of these types of ideas and suggestions down. If we don’t go with an idea, we explain why. It creates a strong culture in which people are willing to share ideas and feel they have a voice. Through 85 years and four generations, everyone thinks you have everything figured out. But family business can be tough. My goal is to be able to hand over a successful business to the fifth generation.”

With the fundamentals and an 85-year track record in place, Huber Supply is built to be successful for generations to come.

Mississippi Welders Supply Company

Distributor

Mississippi Welders Supply Company was founded in 1939 in Mondovi, WI, as the Mississippi Welders & Auto Supply Company. The company incorporated in 1959, subsequently dropping the auto supplies and becoming Mississippi Welders Supply Company, Inc in 1971. The company had a network of dedicated driver-salespeople that served customers in southeastern Minnesota, western Wisconsin and northeastern Iowa. With so much territory to cover, the company expanded to include a Winona, Minnesota store in 1966, which today serves as the company headquarters.

In 1973, Don Peterson, Lou Ottosen, and Lloyd Tomten bought the company. Fifty-one years later, the company remains in the Peterson family.

“The needs of our customers have always been our top priority,” says Brad Peterson, MWSCO’s Chairman and Chief Acquisition Officer. “Our culture is one of empathy, caring, understanding and listening. We listen to each other and our customers and build strong relationships within our teams and with our customers. Having a strong culture where we can rely on each other makes our work enjoyable. When you enjoy what you’re doing, customers and team members notice and want to be a part of it.”

85 years since its founding, MWSCO recently added its 12th branch in Appleton, WI, and is nearing 200 employees. But even as it continues to grow larger, it has never lost sight of its original mission.

“Responsiveness and accessibility. These are two of our core values,” says President Troy Elmer. “We remain accessible to our customers and each other which allows us to respond quickly and effectively.”

He continues, “Gone are the days of supplying a customer with a tank of oxygen and acetylene and showing them how it works. Our customers want full-service solutions to their needs. Yes, we can drop off cylinders of gas, but we need to be the technical experts also. We continue to add services to our portfolio. We have a full line of automation products including robotics, laser welding and cutting, plasma tables and co-bots. We supply vending solutions with vendor managed inventory and vending machines. We have a fleet of CO2 microbulk trucks that take care of everything from bars to restaurants, pools and industrial accounts. Our most recent offering is the installation of fire suppression systems in food trucks and trailers.”

Concludes Peterson, “We are constantly looking for the next growth opportunity and we will stay flexible enough to respond quickly when that opportunity presents itself. Although we have not grown through acquisitions that is something we are actively pursuing. We are also looking at how we can be more efficient in everything we do.”

120 Years

Atlas Supply Company

Distributor

Atlas Welding Supply Company was originally founded as Temerson & Son in 1944. The Temerson family had a scrap business and found that many of their suppliers needed gases and cutting materials to cut the scrap. Temerson became an Airco distributor and planted the seeds for what would eventually become Atlas Welding Supply Company.

The company officially changed its name in 1978 when the Temersons sold the business to an employee, Jack Englebert. Jack, who approached his largest customer, Cain Steel, run by J.M. Cain, to partner in the transaction, changed the company name to Atlas Welding Supply Company and ran the day-to-day operations of the company until 2008, when he retired.

When J.M. Cain passed away, his equity in the business went into a trust managed by his sons. When Englebert decided to retire and sell the business, J.M.’s son, James Cain, who was working in finance, began negotiating a deal with Bill Visintainer to purchase Atlas.

However, upon hearing Bill’s vision for the company, James decided that rather than sell the company to Bill as a sole owner, he would stay on as a partner with Bill and run Atlas together. The two have run Atlas together since then.

At the end of 2020, Atlas partnered with Gas Innovations and helped to form Meritus Gas Partners. In the three-and-a-half years since, the Meritus partnership has grown to 18 partners and its footprint stretches from the Pacific Northwest to the Florida peninsula.

“Atlas still operates independently but enjoys the benefits of access to a vast wealth of industry knowledge we gain from our partners,” says Cain. “Atlas has recently moved our Birmingham location into a facility that is three-times the size of our former location. We will leverage that facility to add more cylinder filling as well as dedicated machine repair and OEM warranty repair.”

As the company celebrates its 80th anniversary, it does so with renewed vigor, secure in a partnership that ensures its future in the industry. Atlas will hold an open house at its brand-new Birmingham facility later this Fall to celebrate.

75 Years

Kemppi Oy

Supplier

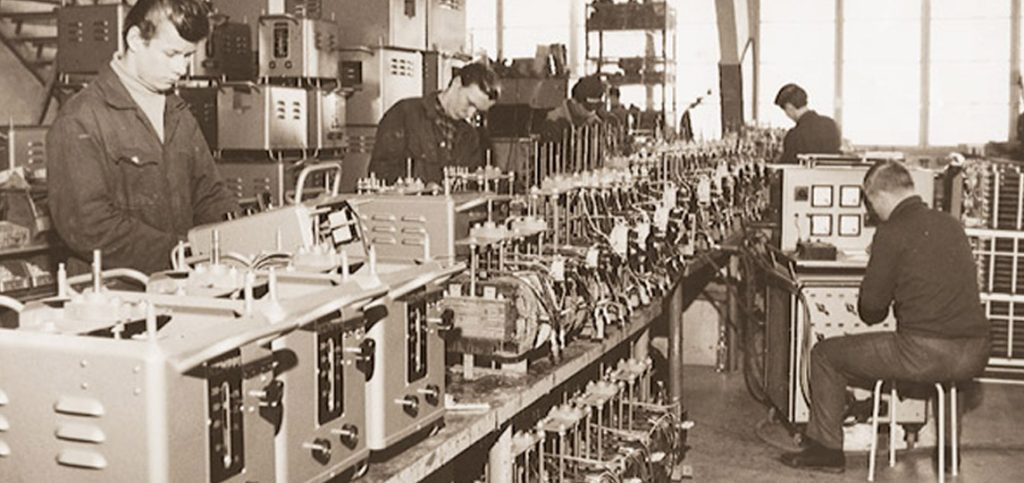

Kemppi Oy was incorporated on May 23rd, 1949, by Martti Kemppi under the name Kemppi Brothers, Inc. The company’s main product was a welding machine. However, with everything in short supply in Finland following World War II, the workshop also manufactured welding carts, concrete and milk carts, soil scoops, fire ladders, and sauna stoves. The company’s business idea was simple and functional: Listen to what customers need and make it for them. This is a template that Kemppi Oy has continued to follow to this day.

Demand for Kemppi’s products grew rapidly, and the company needed more employees and production space. In 1950, the company bought industrial real estate in Pekanmäki, Lahti and hired its first employee outside of the family in 1951. The company embarked on internationalization early, building a global network as far back as 1955. This proactive approach has facilitated successful product launches, introducing groundbreaking innovations to the welding world, such as inverters and digital devices. Kemppi’s history is marked by continuous product development, which has been crucial to its growth and successful market introductions.

Today, Kemppi exports to 70 countries, has subsidiaries in 16 countries and employs more than 800 people.

“At Kemppi, we prioritize business between people. Despite being a high-tech company with ambitious targets, we firmly believe in human values. This philosophy fosters long-term employment and a positive work environment where people thrive. Our employees take pride in being part of the Kemppi family,” says Teresa Kemppi-Vasama, Chairman of the Board. “Customer understanding is at the core of our philosophy. Our DNA is defined by boldness and pioneering spirit, driving us fearlessly towards new frontiers.”

Middlesex Gases & Technologies

Distributor

Middlesex Gases was founded in 1949 by Joseph Martin, Sr. as Middlesex Welding Supply in Everett, MA. Celebrating its 75th anniversary, the company remains a family-owned, third-generation supplier of specialty, medical, and industrial gases and a variety of gas systems, including Bulk, MicroBulk, and Cryopreservation.

Joseph, Sr. set the company up as a distributorship of gases used in the welding and cutting processes. In 1964, Joseph, Sr., opened the company’s first fill plant located just outside of Boston. This move expanded the Middlesex capabilities from just a distributorship of gases to also being able to fill nitrogen, oxygen, and argon in both liquid and gaseous forms. This gave Middlesex a competitive advantage and, more importantly, faster product delivery for customers.

Today, Middlesex has three fill plants in Everett (the company headquarters), Plainville, and Lowell, four supply stores, state-of-the-art specialty gas and medical CO2 labs, in-house dry ice manufacturing capabilities, and a large fleet of trucks and trailers enabling the company to deliver superior gas products and solutions throughout New England whenever its customers need them.

“At Middlesex, we have always kept a finger on the pulse of ‘what’s next’ in the gas industry,” says company President and CEO Thomas “Tom” Martin, the grandson of Joseph, Sr. “My grandfather was dedicated to constantly investing and expanding as necessary to meet his customers’ gas requirements. We continue to stay committed to his initial vision, by consistently building on our capabilities and providing innovative gas solutions for the industries and organizations we serve.”

Tom’s brother, Bo, the previous President and CEO of Middlesex, and now Chairman of the Board, explains how the siblings also have worked hard to keep the familial environment at Middlesex even as the company has experienced tremendous growth. He says, “At our core, we are still a family business, with a tight-knit, relationship-focused culture. But we’re not just close internally as a team. Across all areas of the business, from sales and business development to fillers and delivery, we have developed personal and unique friendships with and mutual respect for our customers, vendors, and network partners.”

As the company celebrates its 75th anniversary, it does so with an eye toward the future. Bo says, “We are confidently moving forward with our focus on supporting the gas requirements of biotech and life sciences organizations. Even though our grandfather could not have known we would pivot down this path, thanks to him, we are located in a highly advantageous area to collaborate with our target customers. We have no doubt the thriving life sciences market is here to stay and our whole team looks forward to helping it continue to flourish by supplying the highest quality gas products backed by exceptional customer service.”

Pat Mooney, Inc.

Supplier

Pat Mooney, Inc. is celebrating its 75th Anniversary in 2024. The company began in 1949, when Patrick J. Mooney invested his 31 years of saw and tool experience and established Pat Mooney, Inc. His philosophy was simple: “To be a successful enterprise, provide reliable products and support these products with good people who are well trained. It’s as simple as that.” Three-quarters of a century later, Pat Mooney, Inc. continues to thrive following those original principles.

Pat Mooney Saws has grown and expanded by establishing partnerships with companies from around the globe that produce reliable and innovative products. In addition, Pat Mooney Saws has continually invested in resources and people to support its products.

Today, Pat Mooney Saws continues to be family-owned and operated by the third and fourth-generation lineage of Pat Mooney, operating from its 60,000 sq. ft. facilities in Addison, Illinois, just outside of Chicago.

“A family-owned and operated business since 1949, we work with top builders worldwide to help companies in North America maximize their sawing performance through innovation, application insight, and technical support,” the company says. “For 75 years, we have helped manufacturers of every size find the right sawing solution for their production requirements. Our 60,000 sq ft headquarters includes an American customer service team, machines under power for demonstration and test cutting, spare parts in stock, thousands of saw blades ready to ship, a grinding shop for sharpening saw blades, and welding shop for the manufacture of band saw blades.”

It concludes, “Here at Pat Mooney Saws, we’re proud of our 75-year history of growth and innovation. We’re even prouder that we’ve remained true to our roots of providing reliable products with optimal support since our humble beginnings.”

Strate Welding Supply Co.

Strate Welding Supply Co., Inc. was founded in 1949 by brothers Russell and Gordon Strate. Both men served their country during World War II and decided to open their own business together after returning home. The company’s original location was in an old gasoline station on Delaware Avenue in Buffalo, NY. As the company continued to grow, it was officially incorporated in 1951.

Strate Welding Supply Co., Inc. continued to expand through the 1960s and 1970s, acquiring a second location in Buffalo and opening branches in Olean, NY and Lockport, NY. They also acquired facilities in Jacksonville, FL; Gainesville, FL; and St. Augustine, FL. The 1980s saw five more locations added in Georgia (Waycross, GA; Jesup, GA; Douglas, GA, and Fitzgerald, GA) as well as the acquisition of an Acetylene Plant and the distribution network of Liquid Carbonic in Western New York.

Today, Strate Welding Supply Co., Inc. continues to look for markets to add and opportunities to grow while serving users in new areas. Offering multiple welding supply stores, a large fleet of vehicles, and some of the highest quality welding supplies and equipment around, Strate continues to strive for excellence, just like it did when the company was founded.

Uniweld Products, Inc.

Supplier

Uniweld Products, Inc. was founded in 1949 by David S. Pearl, Sr. Prior to serving in the United States Navy during World War II in Fort Lauderdale, FL., David had worked in the Steel Mills in his hometown of Pittsburgh, cutting and refurbishing cutting torch tips in partnership with Mr. Werner. The partnership bought The National Torch Tip Company from Dan Marrow and that was the start of the company. When the war was over, David decided that he didn’t want to go back to shoveling snow, so he decided to relocate to Fort Lauderdale, and he and his business partner opened Universal Cutting and Welding Company, which soon became Uniweld Products, Inc. NNT specialized in all types of tips and Uniweld specialized in equipment for this industry. The partnership became two separate family companies in the late 1970’s.

“We’ve always been a conservative company,” says David’s son and current President David S. Pearl II. “When we started out, the entire facility, from reception to shipping was only 5,000 sq. ft.”

But the company continued to grow internally. Today, Uniweld proudly employs more than 200 employees at its Fort Lauderdale Headquarters and is able to service industries around the world, having offices and warehouse facilities in locations across the globe. But even with that robust growth, the company stays true to its family-owned roots.

“From the beginning, Uniweld has been a family-owned and operated business,” says Pearl. “Developing our culture through the decades has allowed us to instill strong family values into our manufacturing processes. Uniweld was there to support our employees through difficult times and situations. As a result, Uniweld has many employees that have been with the company for more than 40 years.”

One of those difficult times was a devastating fire that the company had in 1999.

“We kept everybody on after that. We paid everybody and we found things for people to do. And we were able to start shipping again within a week of that fire,” says Pearl. “I think that’s a testament to the type of people and culture that we’ve built here.”

And because of that longevity and expertise, Uniweld is nimbly able to react quickly to satisfy its customers quickly and efficiently.

“As a family-owned company, we can react faster to satisfy our customers. We are able to invest in new products and get them tested and marketed rapidly,” Pearl says. “We will continue to meet the needs of our customers as those needs change. In 10 years, we see our company bigger, better, and stronger with the ability to react quicker and more efficiently to our customer needs.”

As the company continues its march towards 100 years, it continues to solidify the traits that have allowed it to thrive for three-quarters of a century. It has redoubled its marketing efforts, including its social media efforts to be closer to its customers, and it continues to be the same strong customer-centric culture that has allowed it to thrive for 75 years.

65 Years

Thunderbird Metals

Supplier

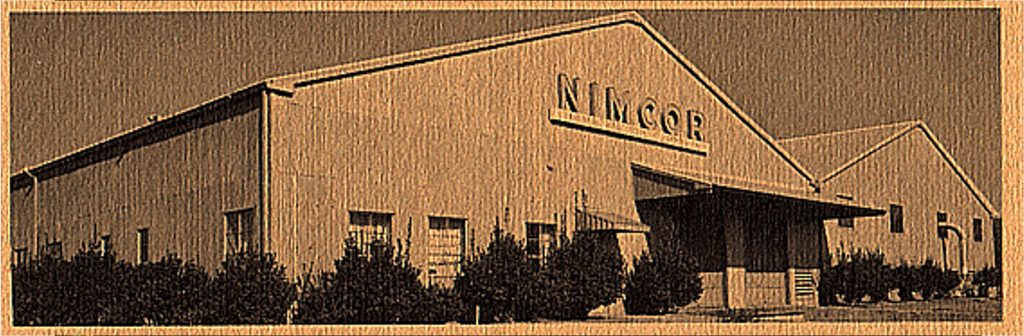

Thunderbird Metals South is celebrating its 65th anniversary in 2024. The company was originally founded as National Impacted Metal Corp. (NIMCOR) and was focused on the manufacture of electrical condenser cans. In 1964, Paul Piper Sr. acquired NIMCOR and renamed the company U.S. Extrusion Impact, Inc. The company transitioned from condenser cans to a deeper focus on Military Ordnance; a focus that remains a key part of Thunderbird Metals South to this day. Throughout the 1970s, the company continued to innovate, developing a 30mm aluminum cartridge case process in 1974 and creating the first airbag prototypes for Morton Thiokol in 1976. In the 1980s, they introduced steel components, including a 25mm cartridge case for the Bradley Fighting Vehicle in 1980 and a lightweight 30mm cartridge case for the Apache Helicopter in 1986.

During the 1990s, the company expanded significantly, particularly in airbag component production, with a major facility expansion in 1993. In the late 1990s, impacted airbag components were phased out, requiring the company to find a new product line to fill capacity. In 1999, the plant began producing aluminum compressed gas cylinder, a focus and core competency Thunderbird Metals South maintains to this day.

“Evolution has been a key to our success,” says Thunderbird’s CEO, Michael Bolos. “The move from condenser cans to munitions was pivotal in our evolution and carries through to this day as we proudly support our armed forces. We spent two decades focused on airbag components, and when they became obsolete, we were forced to reinvent ourselves; developing a core competency in aluminum compressed gas cylinders. The ability and willingness to pivot and innovate continues to be essential to our success.”

To celebrate its anniversary, Thunderbird Metals South hosted a luncheon for all of its employees. The company holds quarterly town halls and holiday meals. General Manager, Michael McDonald, explains, “These regular gatherings are important to us and what helps make Thunderbird Metals South a community.”

Bolos concludes, “65 years took a community to achieve. Those first workers in 1958 laid the foundation for the 100+ individuals that have made their careers and built their families at Thunderbird Metals South in 2024. We stand on the shoulders of giants and are extremely proud of our history and legacy as a U.S. manufacturer. We look forward to guiding Thunderbird Metals South’s innovations and evolution over next 65 years.”

Leonard’s

Distributor

Leonard’s was founded in 1964 by Leonard Bugajewski Sr., along with his wife, Irene, and his son, Leonard Bugajewski, Jr. and his wife, Jean Ann. The concept had actually started much earlier, when Leonard Sr. was at Ohio State University. He left to start a bottling plant called Clio-Cola with his roommate. However, the company dissolved in 1940 due to the product label looking and sounding too much like Coca-Cola. So, he returned to OSU and received his degree.

In 1951, after having graduated and served in the Navy, Leonard Sr. joined the Vernors Ginger Ale Company and took over a failing branch in Buffalo, New York. He brought it back to life and was moved to Detroit in 1956 to become National Sales Manager for Vernors. After fighting for funding for their syrup division he decided to resign in 1964.

Leonard’s Syrups was conceived by Leonard Bugajewski Sr. in the fall of 1964 as a Division of Mavis Bottling Operations. It was spun off into Leonard’s Syrups in the spring of 1965 when Leonard Jr. graduated from the University of Michigan. Leonard Sr’s wife, Irene, worked for Hudson’s Department Store (now Macy’s) during the week, and on the weekends she would go to the shop and do the books. Leonard Jr’s wife, Jean Ann, worked during the week doing all of the customer invoicing and collections. Leonard Jr had his degree in Forestry/Chemistry, so stepping into the role of flavor chemist was a great fit. He started manufacturing the soda using flavors from Foote & Jenks. Soon he realized that he wanted a more unique flavor, so he started consulting with the head flavor chemist at Foote and Jenks and a lifelong friendship and consulting partnership was formed, and to this day, Leonard’s still makes their own flavors.

Starting with syrups and custom installation/service of soda and juices, Leonard’s then ventured into high pressure gas cylinders. Stephen, Leonard Jr’s son, made the decision in the mid-1990’s to invest in Bulk CO2, which made continuous carbonation a possibility for bars and restaurants. Over the years, Leonard’s has branched out into slush, frozen carbonated beverages, draft beer and wine equipment, liquor equipment, draught beer line cleaning, Ice machines, dry ice, blend gas, oxygen and helium.

Today, the company continues to grow and evolve by consistently adding new products and lines of business.

“We keep up with trends and technological advancements,” says Vice President Sherri Iskra. “This year we are rolling out our webstore, where customers can place orders, place service calls, see and print their outstanding invoices, make a payment, send us a message, etc. We are using telemetry more and more on our bulk CO2 cylinders. Customers have an app that they can log into to view their tank, see the pressure of the tank, see how full/empty the tank is, etc. We are constantly thinking of how we can utilize technology to make the customer interface easier and less time consuming for our customers.”

She concludes, “The future of Leonard’s belongs with the younger generation. Two of the six grandchildren in the fourth generation are currently working full-time helping the company grow, and there are four more waiting to succeed and give the service and attention to the family restaurants they serve. The fourth generation is looking forward to expanding and building upon the solid foundation that has been established during the past 60 years. Our customers realize only a family supplier knows how to relate and serve a family business ‘like one of the family.’ We believe that our founder, Leonard Sr, and his grandson Stephen, are smiling down upon us and are proud of our continued advancement in the beverage dispensing industry.”

Weldsale LLC

Supplier

Weldsale Company is celebrating its 60th Anniversary in 2024. The company was founded by Joe Cunningham as Welding Wholesale Company, which was shortened to Weldsale Company in 1976.

Joe began his journey with the purchase of 400 used 5 ft. x 5 ft. “bending slabs” as they were known at that time. He came up with the name of “Platen” in the early 1960s to differentiate his design from the many designs made by lone foundries and a few companies selling their brand of tables. Some of those companies did not bother to emboss their name on their tables. One definition of “platen” is simply a flat plate that exerts or receives pressure.

When Joe sold all 400 of that initial purchase, the phone kept ringing and Joe knew he was onto something. So, he set out to design his own. He incorporated into his design all the best features of the hundreds he had sold. Even today, the design of Weldsale Platens has changed very little since 1976. They remain as thick, robust and nearly indestructible as they were then.

American Industry has been using Weldsale Platens for over 60 years. They are used for many purposes, not just welding. In fact, some companies use Platens simply as heavy-duty metal working benches, with no welding performed. Many companies have been using their platens for decades. Some companies are still unaware of the 100 different clamps and tools available from Weldsale.

But through it all, Weldsale remains the trusted choice for welding solutions, welding platens, welding tools and welding clamps worldwide. “And we are as committed to quality as we were 60 years ago, and we will remain as committed going forward!”