As you head into New York State’s capital city of Albany over the Patroon Island Bridge, you can get a bird’s-eye view of Noble Gas Solutions’ new industrial gas distribution center. Faced with an expanding business and facilities hemmed in by the city that has grown up around it, company CEO J. David Mahoney decided the time was right for the company to invest in some new real estate. In 2015 he found an ideal location not far from his existing headquarters that had better access to the region’s highway systems, and in March of 2016, he began a complete overhaul of the existing building on that site.

Formerly AWESCO, Noble Gas Solutions celebrated its 75th year in business in 2015. The company was founded by Robert Mahony, who, with his son Dennis, built a successful industrial gas and welding distributorship serving the Albany area. Current owner Dave Mahoney (no relation to Robert Mahony) started as a salesman with the company in 1976. He quickly rose through the ranks to become a partner and company president in 1985. One year later, Mahoney purchased the company, which he has successfully led for more than 30 years.

Today, Noble Gas Solutions services a wide swath of New York’s Hudson Valley. In 1996, the company acquired a second location, Walter Smith Welding Supplies, based an hour away in Kingston, N.Y. In 1998, it acquired a competitor in the city of Albany and enlarged its footprint there.

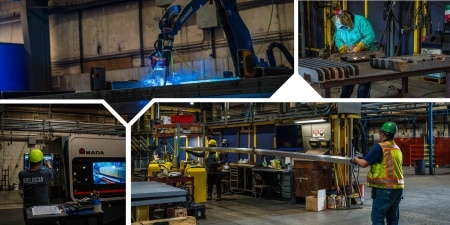

At the heart of Noble Gas Solutions’ success is its razor-sharp focus on achieving excellence in all phases of its business operations. Mahoney explains, “We try to hit the high mark in everything we do, from hiring and training staff to delivering every product in a safe and timely manner to customers.” The company’s motto – “Experience the Noble Difference”– is a testament to how confident the Noble team is in their products and services.

Noble’s Broad Reach

The Hudson Valley is dotted with once-successful mill towns whose businesses have been slowly fading and taking with them lots of gas and hardgoods business. This region has shown resiliency, however, and today serves as a hub for many mid-sized independent manufacturers, fabricators, and service providers. In addition, its economy is strengthened by state government offices, education and medical centers and emerging technology companies, including a new, expansive state university campus focused on nanotechnology. Known as “Tech Valley,” this part of Upstate New York has even gained a large manufacturer (Global Foundries) from overseas.

The company’s broad reach into many markets has helped keep business growing despite economic shifts. Noble’s sales team consists of four outside sales reps, four inside sales reps and one experienced technical sales engineer who is key to training more junior staff members. All reps sell across product lines, both hardgoods and gases.

According to Vice President of Sales Pat O’Donnell, the industrial customer represents 70 percent of the gas business. Specialty gases make up the other large portion of gas sales, 25 percent, with the remainder sold into medical gas markets. In addition to its industrial sales, Noble continues to develop business in a wide range of other markets including construction, pharmaceuticals, healthcare, research and development, beverage and automotive services.

Recently, the beverage sector has been very strong. O’Donnell notes, “We have grown our beverage business over the past four years and it continues to grow at a good pace. Driving this business is a strategic partnership we developed with a local beverage distributor.”

Noble Gas Solutions’ bulk business also has taken off. The company has more than doubled its bulk business in the past six years. Most of that is due to mode change for existing customers, with additional business from new accounts and an overall increase in demand for bulk products in certain markets, like beverage.

Driven by growing product demand from the region’s pharmaceutical companies, Noble got into the dry ice business two years ago. It is the only manufacturer of dry ice, onsite, within 150 miles. O’Donnell explains how, for all applications, “the fresher the ice the better.” There also is a growing demand for dry ice in cleaning applications and Noble has become a distributor of Cold Jet’s dry ice blasting systems.

Tripled Space

According to Mahoney, the company has been in need of more space for at least 10 years, but chose to wait for the right time and place. That turned out to be 10 Erie Blvd. in Albany. After selling both of its older buildings, Noble officially moved to its new home in April.

The size of the expansion is impressive. The company went from two facilities totaling 17,000 square feet to one facility with 50,000 square feet of space, tripling its operational footage. Serving as general contractor, Mahoney headed up the entire project. “Over the years, I have rehabbed plants and facilities but nothing on the scale of what we have now,” he notes. “While the project has gone on longer than anticipated, the end result is well worth it. Situated at the entrance to Albany’s warehouse district, we are the centerpiece of the renovation that is taking place here.”

Everything about the new facility has been carefully thought out to optimize both the customer and employee experience. Mahoney received guidance from GAWDA member Weldcoa on the plant layout. WB Mason helped with office space layout, and an interior designer was used to create unique and functional spaces throughout the building.

One-of-a-Kind Filling

Island, Gas Lab

The centerpiece of Noble Gas Solutions’ new facility is its automated cylinder fill island with palletization. According to Mahoney, “We are the first independent distributor on the East Coast to own a Weldcoa Automated Filling Island. No other company in our market has this capability. Automated cylinder fill with palletization enables us to improve accuracy of fill and get a lot more gas out the door in a much shorter period of time. It’s a terrific competitive advantage for the business and one we are sure will pay off.”

Noble also has invested in a new specialty gas lab, which includes a Weldcoa Digital Lab Assistant (DLA) – the first unit of its kind in existence. With Noble’s new specialty gas lab equipment, cylinders filled on the island at the other end of the building can be analyzed in place, without taking them off line. Tim Fisher, Noble’s lab technician, operates everything from a computer interface within the lab. Noble views the new lab and its capabilities as a great asset to the growth of its business.

Improved Process Flow

The operational benefits of the new facility are significant. Colleen Kohler, director of operations, who is Mahoney’s daughter and represents the second generation involved in managing Noble Gas, describes the transition. “In the old facility, we had just-in-time delivery due to space constraints. It was very stressful and not efficient. Our competitors’ trucks were always on the road before ours. With the new space and our palletized system, everything is visually in front of us. We’re in at 5:00 a.m., print out trip reports, then unload and load trucks. At 6:45 a.m. the drivers arrive, get their tickets, and are on the road by 7:30. The two cylinder handlers working at the loading dock then go over to finish their shift in other operations areas. With this streamlined process, we are able to cut costs and still have happier employees.”

Another great bonus of the new space is the amount of room it has opened up for indoor storage. All non-flammable cylinders are now kept inside and Noble is in the process of refurbishing its stock to make each cylinder look like new.

For the first time, the company is able to build inventory. A picking island has been set up where high-volume gases can be stored in racks. Cylinder handlers can load a pallet from the picking area, fill it and move it to the neighboring loading area, where the entire pallet is loaded right onto the truck. “Our drivers are no longer involved in loading and unloading trucks, which frees them up to do what we pay them for – deliver our products,” Kohler adds.

Cylinder testing is another area that has benefited from the move. Previously, testing was done in a separate building. With everything under one roof, the company has completely streamlined the cylinder hydrotesting process to make it more efficient from a logistics standpoint.

The new facility also has led to some reorganization within the company. Reporting to Kohler are Bill Need and Columbus Buish. In the new facility, the building is divided into production in the north half and cylinder maintenance and inventory in the south. Need now manages the north building and Buish manages the south building. Tim Fisher, who also reports to Kohler, remains in charge of the specialty gas lab.

Expect the Unexpected

As with every move, there were some unexpected sticking points, Mahoney notes. Moving the company’s entire inventory of cylinders and hardgoods created a few issues. Fortunately, the problems have been resolved and everything is now operating smoothly.

Kohler says, “Where safety is concerned, we did not want any surprises. To make sure we had all our ducks in a row from the outset, we invited Mike Dodd, GAWDA’s DOT, Homeland Security, OSHA and EPA safety consultant to go through the building with us. He carefully explained the importance of each safety protocol and served as a great resource.”

Staying Ahead of the Game

Annie Kochneva, director of customer service and marketing, and someone extensively involved in making sure the new space meets today’s sales needs, says, “To stay ahead, Noble Gas Solutions is constantly looking for ways to stand out in a competitive field. This includes an increased emphasis on using the right digital communication tools as well as increased training opportunities.”

Noble is keeping a close eye on the changing sales model. With 50 percent of its revenue generated through the sale of hardgoods, the company takes online buying trends seriously. For now, Mahoney says Noble’s sales have not been hurt by online competitors. He says their customers still prefer to talk to someone, and he believes the younger generation’s lack of industry knowledge prevents them from getting away from a relationship supplier.

If that were to change, Noble is ready. An important part of the new facility expansion is a complete overhaul of the company’s website. When launched, it will include a new e-commerce platform. In addition to hands-on training available in the new facility, marketing is working on providing videos for customers and will be taking a more aggressive approach to digital advertising.

Noble is adapting to new purchasing practices in other ways, as well. On the hardgoods side, where margins are low and online options plentiful, the company is investing in a strong inside sales presence. “Pat [O’Donnell] and I are finding ways to keep our customers happy without having a sales rep in front of them. We want our outside salesmen concentrating on higher margin gas accounts,” Mahoney adds.

There are plans to hire additional staff as the business grows. Noble Gas Solutions sees specialty gas as its fastest growing sector, and the company will look to invest in people for the lab, drivers for delivery and customer service personnel as needed.

Future Strategy

Noble Gas Solutions intends to keep diversifying and broadening its capabilities. According to Kochneva, “Quality of service is what separates us from our larger competitors. We have employees with decades of experience who are ready to serve the customer. We can supply custom solutions or make a special delivery after hours on an emergency basis, as well as answer technical questions. That versatility is what makes us successful.”

Noble Gas Solutions is serious about creating more than just “efficient” working space. Mahoney wants both customers and employees to feel welcome and enjoy their new building. Noble’s new retail store reflects this philosophy with its open design and lots of product display space. An expansive employee lounge is designed to encourage both comfort and camaraderie. It includes a fireplace surrounded by comfortable seating, tables for eating or meeting, and three flat screens.

With the new facility, Noble Gas Solutions presents itself as the premier distributor in its market. With 50,000 square feet of efficiency and a staff devoted to providing excellent products and services to an expanding market that includes pharmaceutical, biotech, beverage and dry ice, Mahoney believes the company is positioned for double-digit growth. He and his team are happy to show you around; in fact, they invite everyone to visit their site to “Experience the Noble Difference.”

Agnes H. Baker is a freelance writer with more than 15 years of experience covering the industrial, medical and specialty gas industry. Based in Massachusetts, she is at: [email protected].