By Bob McEniry

Describing an eight-decade company as “youthful” and “dynamic” might seem like an oxymoron. However, examining the progression of nexAir illustrates a whole different view of the word “old.” The company has evolved and excelled in an industry that has seen significant changes in distribution roles.

Established in 1940, nexAir was formed to distribute packaged gases in a small geography where major gas producers needed service capability. Originally named Standard Welders Supply, the company was initially highly dependent on its gas supplier for producing, packaging, and providing cylinder gases. Over the next 80 years, the whole industry landscape would markedly change, and that small company would evolve into an industry giant. Today, nexAir serves over 35,000 customers through its vast network of 75 locations in 8 states with over 700 employees.

From Humble Beginnings to Modern Day

Standard Welders Supply began as an offshoot of an automobile parts company. Unexpectedly, World War II and its related effects made for a turbulent business climate, resulting in the company being passed through several owners. Amid this chaos, R.Q. McEniry, my father and my son, Kevin McEniry’s, grandfather, was transferred to Memphis. “Mr. Mac,” as he was later known, was an industry veteran and had been with Linde Air Products for 26 years. Joining Linde in California, he had sales and application assignments all over the United States. He arrived in Memphis in 1942 as manager of Linde’s office. In addition to caring for his direct customers, one of his chief responsibilities was to find an owner for Standard Welders Supply. Over the next eight years, Mr. Mac brokered the sale of the company several times. Finally, running out of potential buyers, several prospects told him, “If you think it is such a good deal, why don’t you buy it yourself?” In December 1950, he took his own advice and bought the company. Over the next 70 years, one of three McEniry family members would run the company.

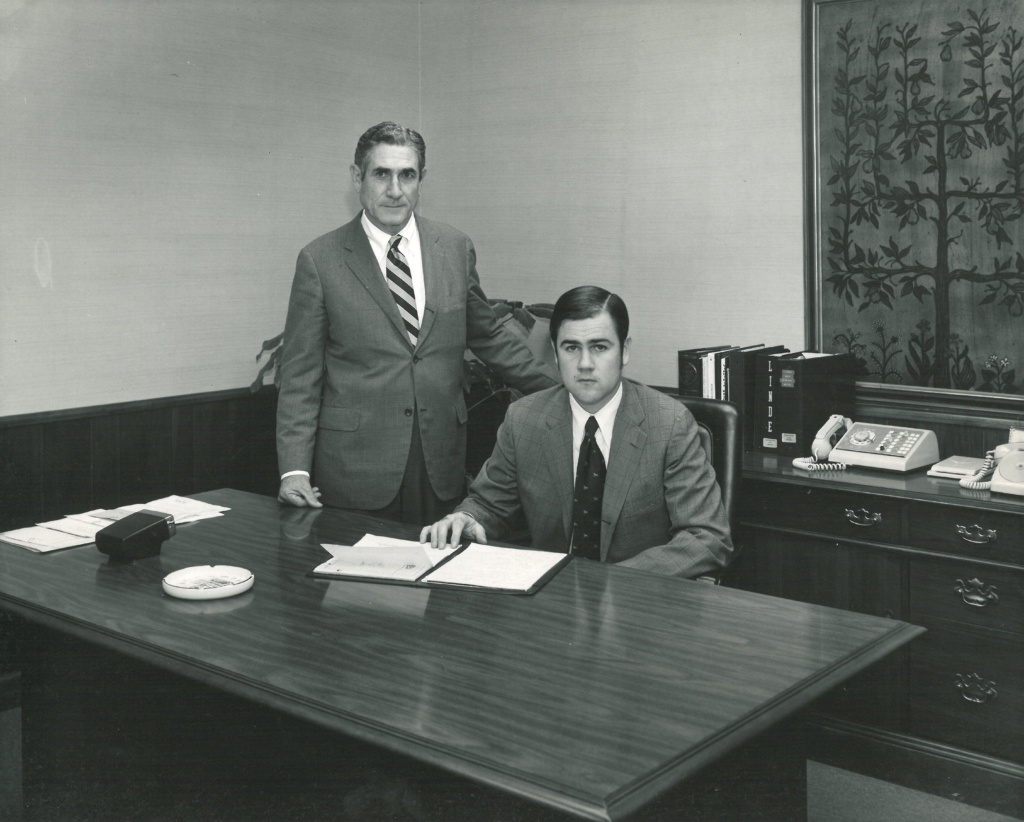

Like most first-generation owners, Mr. Mac was a hard-charging guy, a great salesman, and a do-it-all person. Trained in gas applications, he grew the company quickly. After graduating from Vanderbilt University, I joined my father in 1963. I was immersed into sales before turning to a management role, later becoming President in 1971 and running the business for the next 36 years. In 1994, my son, Kevin McEniry, a third-generation member, entered the company. Likewise, after numerous assignments, completion of his MBA, and thirteen years’ experience, Kevin would take over as CEO.

Developing the Business and Markets Served

The 1950’s and 1960’s were high growth times for the gases industry. As the major gas producers turned their attention to the enormous potentials for gases in the Aerospace, Chemical, and Steel industries, the opportunities for a distributor such as Standard increased exponentially. Adding to those prospects, the late 60’s and early 70’s saw a surge of new plant openings and relocations in Standard’s footprint. However, many of these plants were also coming to rural areas that were outside the traditional Memphis market. To take advantage of these opportunities, the company needed an expanded and educated sales force.

Reinforcing that need was the growth in other market segments. As exciting as the metal fabrication market was becoming, the medical gas market was equally invigorating. Originally, Standard’s healthcare focus had been the home care market. However, as medical gas technologies emerged, Standard found itself in a growing institutional market. Eventually, the company would be providing anesthesia equipment, ventilators, infant incubators, monitors, and a host of disposable products.

Assembling Talent & Maintaining Culture

To meet those needs, the company began building a team that could exploit these opportunities. I recruited my college friend, Bill Vaughan, whom I knew to be a leader. Bill joined the company in 1969 and took over building out the sales team. Over the next 39 years, Bill became a significant member of the management team, retiring as President. Together, Bill and I began recruiting people that could be trained in the multiple disciplines for a high growth company. Particular attention was given to recruiting college graduates. Each trainee would be placed in “boot camp,” that is, they were put in entry level positions to gain exposure to various disciplines across the company. A typical trainee would spend at least a year with stops in cylinder filling, cylinder distribution, warehouse, and store sales. From that training, our management team was able to determine whether they were proficient in sales, supervision, operations, finance, human resources, or any other facet of the business. Many of the group were encouraged to obtain graduate degrees.

“Camaraderie and culture sharing have been the primary goal of our training”, says Bill Proctor, current nexAir President. “I was fortunate to be an early participant in the formation of this program with specific emphasis on personal skills and interaction.”

The cultural payoff has been terrific. Today, the top officers in the company are currently around 50 years of age. Most have worked together for more than 25 years and were the products of that training.

As the company has gotten larger, maintaining culture is a major focus. “Our mission statement: serve selflessly and assist eagerly to create customers for life, defines our culture,” says Kevin McEniry, Chairman & CEO.

The training that began as an informal process is now more formal and measured. nexAir’s Training Director conducts both in person and online training. All employees are enrolled in a training platform, nexAirU, and employees are required to complete courses on a regular basis.

“We are serious about recognizing employees that stand out in our objective,” Kevin says. “Employees from all areas of our company are nominated for the Spark Award, which honors employees that excel in our mission.”

These awards are announced in the quarterly employee newsletter, the airWave. The publication also outlines the company’s successes, achievements, changes, and related news.

Acclimating to Growth

As the business grew, there was a natural expansion to meet the logistical challenges. In the 70’s, Standard began opening branches to expand its geographical and operational reach. Simultaneously, there was a significant change occurring in the industry that effected where those branches would be located. Many first-generation owners with similar timeframes as Standard were now selling their companies. This created opportunities for Standard to buy those companies and expand its markets. Concurrently, there was a surge of industrial plants being built or expanded.

Amid all these dynamic events, one other significant milestone transpired that would forever define the role of the company. In 1984, Linde, who was supplying most of the company’s packaged gases, decided to move out of the packaged gas business. Linde approached Standard with an enticing proposal to buy its Memphis packaging plant. Situated on five acres, the plant offered unique capabilities, including specialty gas and acetylene production. Over the next four decades, the company would acquire an entire block of adjacent property. Today, that plant is 14 acres and processes in excess of 95,000 cylinders per month.

Adapting to Industry Consolidation

Across town, Mid-South Oxygen, founded in 1945, followed a history analogous to Standard. Phil Heppel, one of the founders, died suddenly in 1980. His sons, Scott and Chris, together with Phil’s son-in-law, Chip Valentine, did a wonderful job of bringing the company through this tragedy to grow the business, add stores, and make acquisitions.

Meanwhile, the industry was going through massive consolidation. With that development, competition was no longer confined to local players. Leadership at both Standard and Mid-South spotted a developing opportunity based on the strong synergies between the two companies. On May 1, 1996, the companies merged, increasing the base company by over 60%.

Industrywide, this marriage was a major and intriguing milestone. Two of the largest distributors in the U.S. had combined ownership. Internally, the company had new faces. Scott Heppel of Mid-South took over a big gap in the management team by becoming the company’s first real CFO. His brother, Chris Heppel, headed up the immense medical products distribution business that both companies had grown.

The merger came at a very opportune time for the industry. Chip Valentine, who had become Vice Chairman of nexAir was in line to become the future president of NWSA, now known as GAWDA. Through this experience, Chip made a lot of crucial contacts for nexAir and his own career. Chip would leave the company in 2003 to develop a consulting business based on his experience.

A New Identity

Combining the companies was arduous but rewarding as the synergies of the combined operations began appearing. Simultaneous with the announcement, a new identity was also revealed. The original name, Standard Welders Supply, had been limiting in the vast array of gas markets that the company now served. Similarly, the name Mid-South Oxygen was too regional and constraining. Based on a study with a marketing firm and the company’s emphasis on gas products, the name nexAir was chosen. The genesis for the name was the Latin word “nexus” and the English word “air.” Nexus means a joining of two or more things. So, “nex” coupled with “Air” denotes the company’s expertise in applications of refined air. With the new name, nexAir had clearly defined its focus for gases across a broad spectrum of industries.

nexAir as a Consolidator

Over the last 24 years, while continuing to grow its base business, nexAir completed nearly 50 acquisitions.

The most notable of these acquisitions took place within the last decade. In 2008, nexAir entered the Georgia market with the acquisition of a specialized company. Praxair was nexAir’s principal gas supplier, but Praxair’s packaged gas arm, Praxair Distribution Inc. (PDI), also had a presence in the same area. With nexAir’s aggressive growth as a regional distributor, a logical progression was a joint venture to consolidate costs and eliminate duplication. PDI’s locations in Georgia, Alabama and Tennessee were included. The success of this venture led to another transaction. In late 2015, nexAir bought PDI’s position in Praxair Distribution Southeast (PDSE), a venture that formed in Florida and southern Georgia. With the completion of these deals, nexAir’s market stretched from the western borders of Louisiana and Arkansas through the northern border of Kentucky and to the tip of Florida, including some business in the Caribbean.

Expanding Product Offerings

nexAir’s considerable volume in the CO2 market led to an examination of all CO2 products. In 2008, nexAir entered the dry ice business with a calculated buy of an existing operation in Brandon, MS. This venture was given the name nexAir Carbonic. Strategically, this move gave the company increased access to CO2 and a larger presence in food, pharmaceutical, and shipping markets. This presence was enhanced substantially in 2016 when nexAir purchased two additional plants from gas producer Air Liquide. The first was a CO2 production plant and the second was a Dry Ice production facility, both located in Millington, TN.

Another market that nexAir strategically wanted to strengthen was the medical and healthcare gas segment. That opportunity came in late 2019. When Praxair and Linde merged their global businesses, both companies had many U.S. locations. Seventeen of Linde’s packaged gas locations fell in the nexAir arena. Using the same logic of the former PDI acquisitions, the Linde LifeGas healthcare business was spun off to nexAir. Now branded nexAir Healthcare, these locations compliment the nexAir footprint and increase nexAir’s penetration into the health care segment.

Improving Efficiency and Providing Support

nexAir began operating the Linde assets on January 1, 2020. One of the prized parts of the purchase was a much-needed packaged gas plant southwest of Atlanta. In its 1980’s heyday, operating as Holox, that facility was the largest plant of its kind in North America. However, through industry consolidation, the plant’s volume decreased drastically. Conversely, nexAir’s need in the same geography had grown and its needs were substantial. nexAir’s volume had long outstripped its Norcross, GA filling capability and the company had been searching for a new location. The Linde facility was perfect.

The gases industry stands to markedly benefit from the transaction. The plant fills a gap for the industry distributors. With nexAir’s volume in place, the plant can now support distributors in an immense geography. Scott Neal, a nexAir veteran with more than thirty years in the industry, was recently appointed Vice President for Wholesale and Distributor sales. The move was to separate nexAir’s traditional sales team from the needs of other distributors. Scott recognizes what nexAir uniquely represents to the industry.

“The days of running a small acetylene plant are long gone. The industry depends on high volume plants like those nexAir has in Memphis, Okeechobee, and Union City. In addition, nexAir’s ability to produce non-conventional, high purity, and specialty gases make us a great supplier for wholesalers. In the past, those needs were provided by the major producers. Now that most of those suppliers have exited the market, the conventional distributor has lost that source and accompanying support. Although some are competitors to nexAir, those distributors are servicing markets beyond our reach. nexAir recognizes that its traditional sales team is not necessarily the channel to all markets. Having those products available to industry distributors is a win-win for all parties. Likewise, the professionalism of the nexAir Plant Operations Team, their ISO recognition, their regulatory compliance, and their attention to detail make nexAir a logical choice,” says Neal.

Use of Technology

Despite its age, nexAir is aggressive in its use of technology. The biggest payoffs in technology have been in projects to control nexAir’s costs. Mike Enders, EVP of Operations, explains, “With all the interns and young talent that the company has recruited, we have the resources, and it is just a matter of challenging their intellect. Rather than have these talented people waiting for a ‘job to open up,’ we test them and put them to productive use. In their initial training, the trainees get a feel for the culture and the business. Now, we immerse them in problem solving”. Projects currently underway address warehousing, logistics, routing, financial control, website design, and a host of other tasks.

The current pandemic has accelerated the use of technology, especially in the communication arena. Online meetings are becoming the rule rather than the exception, saving significant amounts in travel expense. However, the implementation of other communication tools is far more thorough.

“As an example, we have two Support Centers, one in Memphis and another in West Palm Beach,” Enders says. “Inside those centers, prior to COVID-19, we already had a significant number of these support people working remotely. With a concerted training effort, we took this technology and spread it throughout the company.”

On the financial front, nexAir is actively working with suppliers and customers to decrease dependence on paper transactions.

“If anything, the pandemic has hastened our use of technologies.” Mike adds.

Looking to the Future

2020 marked the 80th anniversary for nexAir. Looking to the future, management is confident of continued growth but is constantly aware the business landscape is everchanging.

“After 80 years of history, we know that each decade is different. nexAir will evolve to meet whatever lies ahead,” Kevin McEniry says.

2020 has been rewarding for the company. Not only was 2020 its 80th anniversary but it was one of recognition. In June, nexAir received one of the nation’s most prestigious awards. Deloitte Private and The Wall Street Journal named nexAir among The Best Managed Companies in the United States.

“Criteria for the recognition was based on strategy, execution, and financial performance,” says Milton Lovell, nexAir CFO and General Counsel. Kevin McEniry added, “These attributes echo our mission and values. While we are proud of the national recognition, we are even more proud of our heritage.”