SafTCart’s culture has allowed the company to become an industry leader in cart manufacturing.

This winter, I made my first trip ever to Mississippi to check out SafTCart, located in Clarksdale, about an hour and a half south of the Memphis Airport. With 150,000 square feet of manufacturing space inside several buildings on a 15-acre lot in a business park, SafTCart continues to expand its footprint within the industry. I was fortunate to be hosted on this visit by Executive Vice President Jim Herring, who was as gracious a host as you would expect if you’ve met him at a GAWDA Event before. Thanks to Jim and the entire team at SafTCart, I got a behind-the-scenes look at how large of an operation SafTCart has become over the years.

In 1969, Walker Welding was a typical GAWDA distributor. With eight branches in Mississippi, its stores sold welding equipment with the complementary gases needed to operate them, and a young Jimmy Walker Sr. and his wife, Helen, at the helm. Twenty years into Walker Welders, in 1989, they started manufacturing cylinder carts in a back shop area. From there, they began mass-producing the carts under the brand SafTCart.

With a name like SafTCart, you’d obviously expect to see a bunch of carts throughout the facility. However, their business has exploded way beyond just the carts. Their core business has expanded to seven different categories of products, including carts, cages, cradles, pallets, racks, truck bodies and trailers, and now, Pods, which are essentially large cages for micro bulk tanks. SafTCart’s largest growth in recent years has been in their truck beds/trailers, where they have a dedicated building with around 20 employees assembling nearly 150 truck bodies per year.

Another area of growth for the company has been the galvanized aluminum offering, which essentially provides their existing steel products in a more durable galvanized aluminum option. This is particularly beneficial for distributors who operate in winter weather conditions and are exposed to road salt, which can cause steel products to rust over time.

Throughout the years, SafTCart has continuously reinvested in the business, adding equipment to help streamline processes and become self-sufficient. Things that were previously outsourced are now handled in-house due to these investments. Three laser cutting machines, a steel bender, a custom conveyor system, two giant ovens, and numerous welding machines are just some of the equipment in their arsenal for manufacturing steel products.

The increased production over the years has made SafTCart an anchor employer for Clarksdale, employing nearly 130 people within a 70-mile radius of the company’s headquarters. A common theme among both administrative and warehouse employees is that many have been with SafTCart for at least a decade, with some approaching 30 or more years of service. Most of the staff work in production/shipping, while they also have their administrative offices on-site. A recent acquisition has added 20 employees, all located in Charlotte, at the Carolina Piping facility.

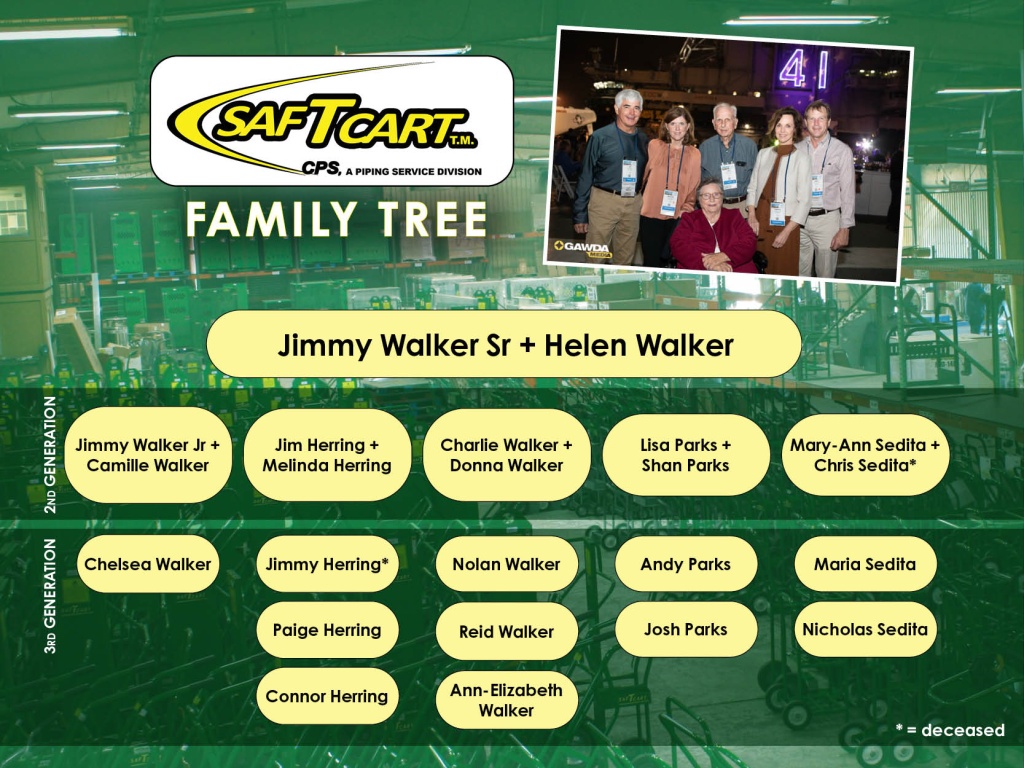

Most relatable to many GAWDA members – both distributors and suppliers – is the family legacy within the business. Each member of the Walker family has played a pivotal role in its growth over the years. Currently, there are three generations involved, each with its own defined roles. Starting at the top, Mr. Walker and Helen still travel to various trade shows to promote and maintain their generational relationships. Representing the second generation, Jimmy Walker Jr. serves as the CEO; Jim Herring, EVP and COO; Melinda Herring, Sales Ambassador; and Charlie Walker, Sales Manager. The grandchildren currently involved in the business include Reid Walker, Operations; Connor Herring, Marketing, Quality Assurance and IT DIrector; Andy Parks, Operations; and Nolan Walker, Operations. At one time or another, each member of all three generations has contributed to the company’s success.

The culture of SafTCart reflects these family values and focus. Even the employees who are not related to the Walkers are still very genuine in their interactions, and you can tell they treat the business as if it were their own. Long-time employees like the infamous IT Andy, in customer service; Ruby in shipping and logistics; and Tishana in accounts payable. In production, key longtime employees like L.A. Walker, Pallet Line Manager and Welder; Terriz Thigpen, Assembly and Shipping; and M.C., in shipping; have been with SafTCart pretty much since the beginning. A more recent hire with a significant impact was Billy Monfort, the truck bed engineer, who joined in 2020.

What I observed during my visit is that SafTCart is a business that has been built on hard work and being scrappy. Real war stories are what you could point to as being the difference between winning and losing in business. Just the day before I arrived, they had one of those war stories, with equipment issues causing the team to find fast solutions to keep production going, resulting in team members working well past their scheduled work time. However, they stayed late to ensure that production was on schedule the following day.

Other, less urgent war stories, such as picking up second-hand equipment from another business and incorporating it into their operations, are common to hear on the floor. These monster machines had to be disassembled before being transported and then reassembled on site at SafTCart. I could tell from Jim’s voice that he was likely involved in many of those capital investments, alongside other family members who contributed to the facility and equipment expansions, helping build the operation into what it is today.

GAWDA members across the country likely have their own personal war stories in their businesses, similar to what SafTCart has experienced in its 50+ year history. Those war stories are what make businesses what they are today. In the case of SafTCart, they have become a proud 3rd-generation, world-class manufacturer from Clarksdale, Mississippi.