Rooted in the magnificent Pacific Northwest, OXARC is a leading U.S. industrial gas distributorship with over 360 staff members and 22 locations serving the tri-state area of Washington, Oregon and Idaho. Founded by Jerry Walmsley, the company began with his purchase of Northwest Oxygen Company in Spokane, Washington, in 1968. From that first shop with 15 employees, Jerry and his team developed one of the largest industrial gas distributorships in the nation.

Jerry remains active in the business as chairman of the board, and his daughter, Jana Nelson, who has been with the company since 1975, serves as OXARC’s president. The management team that supports Jana in the company’s mission to be the most complete single-source supplier with the best customer service in its region includes a mix of new and long-term employees. Executive Vice President Mike Sutley has been with OXARC since 1972 and anchors the overall business. Keeping the facilities running smoothly is Vice President of Operations Don Nelson, Jana’s husband. Newer to the team is Jason Kirby, vice president of sales and general manager, who keeps a close eye on sales. The third generation of Walmsley’s is on board at OXARC as well, with four of Jana and Don’s children hard at work throughout the company: two in human resources, one as an IT professional and one in the company’s fire division.

Thriving on Diversification

One of the hallmarks of OXARC’s success is its well-diversified business, which was developed through a combination of organic growth and well-timed acquisitions in new or growing markets. Gases and hardgoods represent the lion’s share of revenue, 45 percent and 25 percent, respectively, but the company is also strong in safety (13 percent), fire equipment (10 percent) and industrial sales (6 percent), which includes large-scale equipment. The interplay between these divisions drives OXARC’s steady 5–6 percent annual growth rate.

“We started out as a basic welding equipment and gases supplier, but have sought to diversify our interests as a way to grow and protect our business,” said Jana. “The first move outside of our traditional market was the 1995 purchase of the Columbia Fire Equipment Company. It was a success from the start. Today we sell and service fire extinguishers, carry related equipment like first aid kits, refill extinguishers and conduct fire equipment inspections and training. The fire division then expanded into fire suppression systems, off-road vehicles, paint booths and document storage rooms. We are now evaluating advanced clean gas systems for future growth.”

OXARC’s main markets revolve around the region’s agricultural industry. Mike Sutley explained, “We cover a lot of rural areas. The region’s growers and food processors are a big source of revenue for us. We sell a lot of refrigerant gases, which are used to both freeze and store food products and in cannabis processing.”

OXARC’s customers include giants like ConAgra and Tyson foods. Supplying the local pulp and paper industry is another solid market for OXARC. And the region’s growing urban areas, like Portland, Oregon, are creating plenty of fabrication and construction-related business.

Location, Location, Location

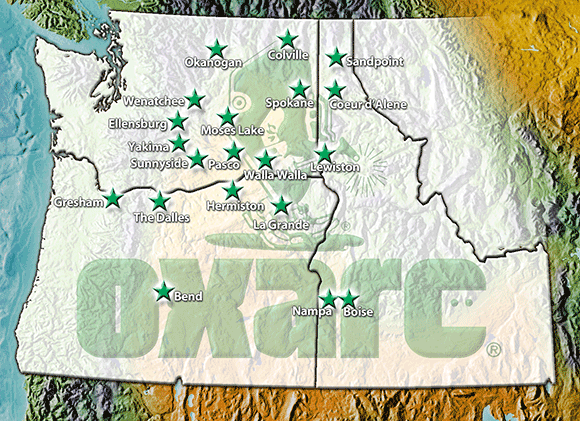

OXARC’s territory takes in an incredible 1,000 square miles of the Pacific Northwest. With excellence in customer service critical to its mission, OXARC has 22 facilities positioned around the tri-state region, including 20 branch locations.

Right in the middle of OXARC territory is Pasco, Washington, where the company has centralized its production and distribution operations. With bulk tanks, transports, a 25,000-sq. ft. warehouse for hardgoods, a welding school and both a state-of-the-art, fully automated Weldcoa industrial fill plant and a specialty gas plant, Pasco serves as the company hub. OXARC has two additional fill plants — one is in Spokane, Washington, and the other in Gresham, Oregon — and 11 other locations with liquid tanks to support the specific needs of customers throughout the region.

Bulk CO2 tanks, as well as oxygen, nitrogen, argon, nitrous oxide, medical oxygen and liquid hydrogen tanks, are located in Pasco, as is a fleet of trucks that includes everything from tube trailers with fill capacities from 45,000 SCF to 180,000 SCF to trucks that support microbulk systems.

In addition to its branch locations, the company has two unique facilities. OXARC’s Springfield/Spokane location is dedicated to cylinder production, the wholesale fire group and its fire division, the certified welding inspection (CWI) division and one of OXARC’s welding schools. In its Vancouver, Washington, facility, OXARC provides cylinder testing and cylinder refurbishing services.

Organizing this broad territory and diversified product and customer base is OXARC’s sales management team. To keep this complex business on course, Mike explained: “Our sales management team is divided into two territories, North and South, and we have a team leader for our CWI and safety divisions as well. This group is in constant communication with each other, coordinating business across branches and divisions. To encourage team playing, there are no sales commissions. In fact, all of OXARC’s employees are either salaried or hourly. Everyone is eligible for a bonus each month if the company meets its gross margin goal for that period. This system has worked very well for us.”

Jana noted that from an operations standpoint, the company’s membership in GAWDA has been instrumental in helping them with DOT compliance, training and safety issues, especially in filling processes and with the FDA.

The Gas Business

Representing 45 percent of all revenue, OXARC’s gas business is its most significant division. CO2 is its largest selling gas followed by nitrogen, argon, acetylene, other specialty gases, oxygen, chlorine and helium.

OXARC sells a lot of CO2. According to Mike, the company has an average run of 2,000 tons of CO2 per month. Agriculture is a big driver behind these sales, with up to 500 tons of CO2 a year going to a local hops producer and an enormous amount of CO2 in the form of dry ice going to processors of the region’s less traditional crop — cannabis.

With four ice machines operating in three locations, the company both produces and sells dry ice products. OXARC got into the business back in 2009, supplying mostly pellets for dry ice blasting and packaging for small labs. “Today, we still sell to labs, but the real growth is driven by the cannabis industry, which uses dry ice as part of the extraction process for cannabis processing,” reported Mike.

OXARC’s nitrogen business is finding renewed strength in the oil and gas market where it supplies nitrogen for purging and pipeline testing. The company can provide up to 6,000 psi for pressure testing from its nitrogen trailers. These services are in increasing demand by natural gas companies, refineries and even gasoline businesses, according to Mike.

Acetylene has been part of the OXARC portfolio since 1981, but its acetylene business really took on significance in 2011 when the catastrophic explosion at the Louisville, Kentucky, plant of Carbide Industries created a shortage of the raw material needed for acetylene production. OXARC was able to expand and upgrade its acetylene plant in Pasco at that time and supplied major gas producers like Praxair and Linde (now Messer) with product. Today, OXARC is a major acetylene supplier in the Northwest, producing 1.5 million cubic feet of product per month.

Specialty gases are another important and growing part of OXARC’s portfolio. The company acquired its first specialty gas plant in 1987 and produced mainly ultra-high purity (UHP) gases. Today, its state-of-the-art spec gas facility in Pasco, designed and built to meet its customers’ needs, can produce gases in parts per million. Extraction gases, such as N-propane and N-butane, which are used in processing cannabis, represent the company’s fastest growing specialty gas market. In fact, OXARC now has three 12,000-gallon tanks of extraction gases in Pasco to support this business.

Mike reported that in addition to creating a huge spike in gas sales, “Extraction gases have created a whole new market for related equipment, especially from a safety perspective where we see a very positive growth in providing supplies like gas monitors and gloves. It is in areas like this that OXARC’s diversification allows it to participate in the entire supply chain for goods and services, not just the gases.”

Chemicals is yet another spoke in OXARC’s wheel of diversified offerings, and it got its start in an interesting way. When an Idaho company that OXARC was supplying with chlorine shut down, one of its employees, Cristian Stanciu, approached OXARC about getting into the chemical business. Cristian joined OXARC in 2003 and is the company’s top chemical salesman today. OXARC’s main chemical product is sodium hypochlorite (NaOCl), which is used in potable water and wastewater treatment and for purification in swimming pools.

Looking ahead to future demand in the gases market, OXARC has the capability to supply high-pressure hydrogen up to 6,000 psi, something no other company offers in the Pacific Northwest. With the belief that hydrogen as a transportation fuel is a growing market, OXARC is ready for those applications that require higher fill pressures.

Safety

Safety is the next most important part of OXARC’s business after gases and hardgoods, and OXARC’s diversification allows it to cross-sell into safety from its many markets. As mentioned, the recent development of the cannabis industry has been a big boost to the company’s safety division. Training is another important element.

In the safety division, a big part of the company’s sales strategy lies in education, and OXARC runs some unique training programs. “We have a fairly large safety division,” said Mike, “and the training programs we develop with our vendor partners have proven to be a great way to grow our sales.”

Used in training are the OXARC/Honeywell fall protection trailer and OXARC/Honeywell confined space training unit — both of which are mobile and can be taken to customer sites. All employers want to keep their workers safe and OHSA rules and regulations require training, especially for work in confined space environments, so OXARC’s mobile training is in demand. OXARC carries much of the safety equipment related to this training, and Mike noted that “the training has created both sales and customer loyalty.”

Special Service Capabilities

OXARC has found that diversification, especially into services, is not only a good way to grow the business, it’s also a good defense against recessionary forces.

One of the many services OXARC provides is certified welding inspections. Its certified welding inspection division was launched in 2001 with two inspectors. Today, CWI has 10 certified personnel who inspect projects in OXARC’s region and beyond. “There is a lot of new construction in the West that requires welding inspection services, and our CWI division has been very successful in capturing this business,” reported Jana.

Another service area that OXARC has developed is welding repair. Jana noted that during the recent recession, when sales of new equipment were down, the company’s welding repair business soared, filling in revenue gaps and providing a valuable service to their customers.

High-pressure compressed gas cylinder fill capability up to 4,500 psi is another hard-to-find service provided by OXARC. “We have lots of miles between the communities we serve,” explained Mike, “and these cylinders can hold about 25 percent more product. That means less handling for us and our customers, who tend to be too small for bulk but too big for regular cylinder racks. We build HP cylinder packs by order, which allows our customers to store the quantities they need.”

OXARC also has three locations in Washington — Wenatchee, Okanogan and Walla Walla — that can provide cut steel for customers. For these centers, OXARC buys steel in bulk and cuts it to order. The company also makes its own bandsaw blades.

The Welding Schools

The company’s two welding schools offer yet another much-needed service at a time when welders are in short supply. OXARC began its welding school in 2001 and today has programs for beginning, intermediate and advanced welders at its Spokane and Pasco locations. The program’s job placement rate stands at 95 percent.

The school also offers OXARC the opportunity to get young people interested in welding. It sponsors the Boy Scouts’ welding merit badge program each year, complete with a helmet for each candidate, and hosts Iron Clad, a program that introduces welding as both an art and industrial technique to high school students. It also provided OXARC welding school scholarships to four graduating high school seniors this year.

The welding schools also serve as an in-house resource. OXARC employees are what make the company successful, and the retirement of many of its long-term staff presents a challenge. Finding and retaining new employees can be daunting. After all, few people outside the industry have any idea what is involved in an industrial gas distributorship.

To address this knowledge gap and get people excited about career paths within the industry, OXARC educates its new employees by offering welding classes. During a three-day course at its welding school, new employees get to use many of the products OXARC sells, gaining a better understanding of customer needs. Jana reported that this program has been very successful.

New Initiatives

OXARC has been in business for over 50 years and today is hard at work preparing for the next 50. “I plan to see the company meet the $100 million-plus mark in revenue this year,” related Jana.

One of the company’s current initiatives is a complete revamp of its website. OXARC is looking forward to rebuilding the site so that it can expand its ecommerce options and provide more mobile apps.

OXARC is also launching private branding for all of its welding consumables. The company provides very high-quality goods at competitive prices, and its branding initiative is intended to make OXARC customers aware of its value-added products.

On the management side, Jana explained that she is planning on developing a policies and procedures manual that will help define and streamline the company’s diverse operations.

For the future, OXARC is working on introducing cylinder tracking — a must-have in the distribution business today. This represents a very large undertaking, and the company is in the process of carefully evaluating its options.

OXARC considers staying ahead of the markets one of the cornerstones of its success, and Jana emphasized that this is how the company will continue to move forward: “We have built OXARC one new business venture at a time, and we will continue to develop platforms that serve new customers and applications. With the next generation of the Walmsley/Nelson family on board, we plan to strengthen our position as the most complete single-source supplier in our region, with the most dependable and knowledgeable team.”

Jana added: “We are very proud of our employees, and they are valued greatly. I have a plaque hanging in my office from the late ’80s in my father’s beautiful writing. It states, ‘This company shall continue forever.’ That was his dream, and both my family and our employees plan on honoring that dream.”