Congratulations to all GAWDA Members celebrating anniversaries in 2024

The past several years have represented a dramatic shift in the gases and welding industry. We’ve seen the industry get leaner, as M&A activity continues to shrink the industry, while the internet, and the rise of AI and other technology makes the entire world smaller and more connected. But, in a larger sense, the fundamentals of the business remain the same. This industry remains a relationship business. While the X’s and O’s may look different today than they did 100 years ago, the overall playbook remains very similar. And there’s a reason that GAWDA members continue to persevere year after year, generation after generation. While technology continues to advance, the culture and the infrastructure remain the same. GAWDA members are built on solid bedrock principles, which allow them to continue to thrive, no matter the technology. Congratulations to all those GAWDA members who are celebrating anniversaries in 2024! And if you have a milestone anniversary coming up in 2025 and would like to be featured in this issue next year, please reach out today at [email protected].

Jump to Section:

55 Years

Acme Cryogenics

Supplier

Acme Cryogenics was founded in 1969 as H&B, a general machine shop serving the manufacturing base in the greater Lehigh Valley, Pennsylvania. The company changed its name to Acme Screw Machine Products a few years later and began to focus on the industrial gas industry around 1977 when the Compressed Gas Association standardized a Liquid Transfer Fitting that Acme was manufacturing. By then, Rod Fink became the sole owner, and the company continued to grow through acquisitions and organic development of new capabilities. Eventually, the name was changed to Acme Cryogenics to reflect its industry focus.

Acme Cryogenics has grown by continually meeting the expanding needs of its customers and the industrial gas applications market. This includes adding new products like Cryogenic Vacuum Jacketed Valves, Gas Manifold Control Piping, Vacuum Jacket Piping, UHP Delivery Systems, and Cryogenic Vaporizers, as well as expanding into virtual industries like Aerospace and Hydrogen. The demand for installing and maintaining these products has also offered significant growth opportunities. Acme’s ability to provide technical, problem-solving expertise has been crucial in forming long-term partnerships and winning customer trust. Recently, Acme Cryogenics was acquired by Dover to become part of OPW Clean Energy Solutions, incorporating Rego Products, which has further bolstered its growth, product offering, and market presence. Today, Acme Cryogenics employs 225 people and operates four manufacturing locations: Allentown, PA; Ball Ground, GA; Lonsdale, MN; and Oxnard, CA. Additionally, it provides Field Services from six regional hubs.

Acme Cryogenics’ culture emphasizes technical excellence and long-term customer relationships. The company’s ability to provide innovative solutions to underserved segments of the industry has been central to its longevity and success. A strong culture has maintained high standards and fostered a dedicated workforce.

The company’s biggest differentiator has been its long legacy of technical expertise and ability to solve complex customer problems. This has allowed Acme to build solid partnerships and establish a reputation for reliability and innovation in the industrial gas market.

In the next 10 years, Acme Cryogenics plans to continue growing alongside the cryogenics industry and its customers in North America and globally. The company will keep expanding its product offerings and maintaining high standards of quality and service with a great focus on Industrial Gas markets and the fast-paced evolving Hydrogen Economy.

To celebrate its 55th anniversary, Acme Cryogenics will have a celebration luncheon for the company. The company notes, “Acme Cryogenics takes pride in its dedicated workforce, with over 20 staff members having been with the company for more than 20 years. This dedication is highlighted by Dave Edge who recently retired this year with a total of 46 years and Tom Stroble, who has been with the company for 46 years.”

Dynabrade, Inc.

Supplier

Dynabrade began in 1969 with one inspired idea. Walter Welsch, Dynabrade’s founder, developed the first Dynafile® Abrasive Belt Tool as a method of improving the task of hand-filing metals and other hard surfaces, while making this process quicker and easier than ever before.

Walter started working for an abrasive manufacturer in 1951, selling coated abrasives. His first sales territory was in Buffalo/Rochester, New York. At that time, Curtis Wright, a prominent aerospace manufacturer, was in Buffalo and was one of the first companies to manufacture jet engine blades. This led to Walter being one of the first people ever to see abrasive belts being run over small, one-inch diameter contact wheels, grinding convex areas on high alloy metals. Until then, splices on abrasive belts could not do that.

Wurlitzer, the world-famous jukebox manufacturer, was also one of Walter’s accounts. While visiting Wurlitzer, Walter witnessed a lady filing square holes in an aluminum casting that was used as a jukebox grill. The idea occurred to him that a portable abrasive belt running over a 5/8″ diameter contact wheel could file those holes much faster. That moment was the beginning of the Dynafile® and the true start of Dynabrade, Inc.

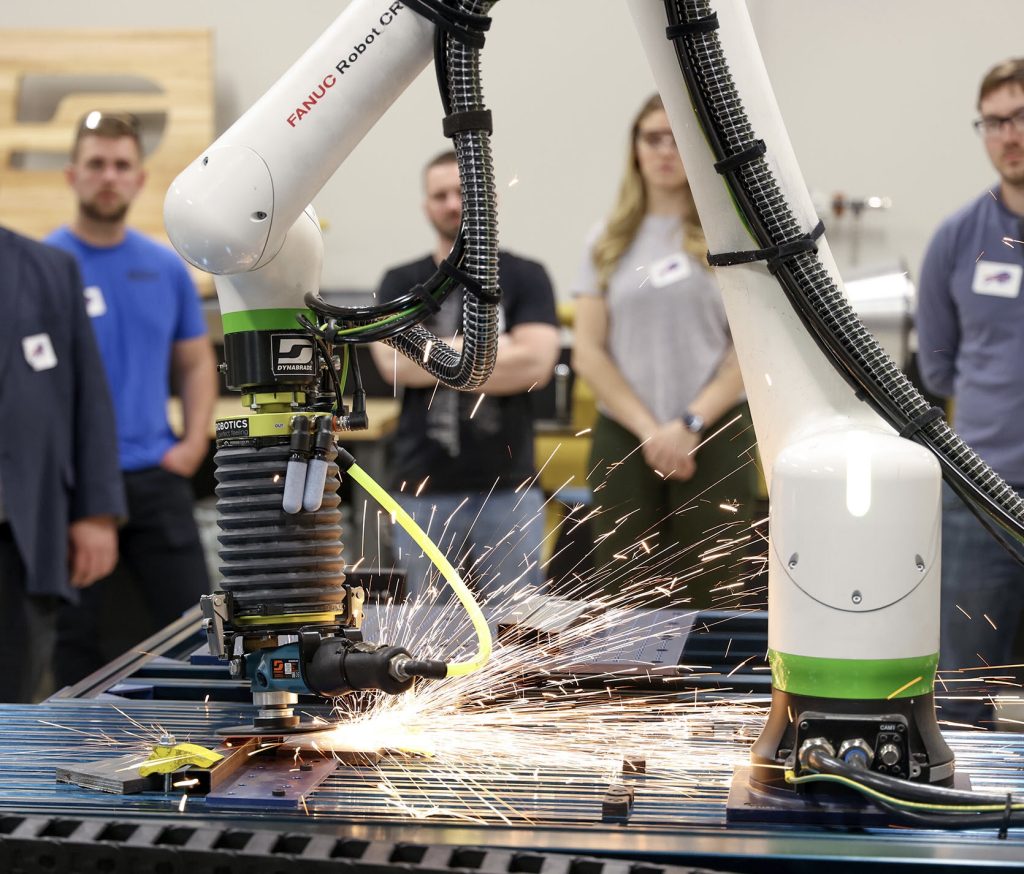

Through its continued innovation and entrepreneurial spirit, Dynabrade has thrived for 55 years, continuously upgrading the product offered, through extensive research & development based on market needs and new technological advancements in the tool and abrasive industries. Today, through the continued hard work and determination of its employees, Dynabrade has earned a reputation for excellence and a position of leadership in the innovative design and manufacturing of unique portable pneumatic abrasive power tools, related accessories, and dust collection.

The company now offers more than 1,000 tools for material removal and surface treatment, as well as thousands of abrasives and necessary accessories so that all industries can solve any of their surface treatment needs.

“We are easy-to-do business with and supply these products quickly to customers through a worldwide network of professional distributors. The perfect finish begins and ends with Dynabrade,” says Welding Supply Channel Specialist Alexis McDermott. “Since our founding, Dynabrade has committed to being a U.S. manufacturer. We have grown into a global company with worldwide distribution, having subsidiaries in both Europe and Asia. Our company offers a complete product line of process solutions, including pneumatic abrasive power tools, clean air solutions, industrial vacuums, abrasives and accessories.”

Says McDermott, “In 10 years, I truly believe our sales will be diverse, expanding from primarily tool driven, to having more equalized sales with abrasives and Automation. Automation has the potential to become our strongest growth driver in the next 10 years, along with expansion into more channels, like Welding and Automotive Refinishing.”

Genstar Technologies Company, Inc. (GENTEC)

Supplier

In 1969, Thomas Kuo saw an opportunity for growth in the area of industrial regulators and cutting equipment. And so, he launched Genstar Technologies Company, Inc.

Over the next 55 years, Genstar Technologies has emerged as a global provider of high-quality pressure regulators, fittings, valves, welding apparatus and various gas control and handling devices.

High quality products, competitive pricing and continual technological innovation have fueled Genstar’s steady growth for more than half a century.

“We strive to continuously improve our product lines while developing innovative products for diverse markets,” the company says. “Our distributors take pride in supplying Genstar’s products because they offer users significant value. Products are produced, assembled and tested by an experienced and dedicated work force that is committed to product integrity and excellence. In addition to their high quality, the products are interchangeable with most major brands.”

Says Larry Meyers, Director of Industrial & Medical Sales (Americas), “It’s very important to us to give good customer service. We see ourselves as a major player in the market. We’re not box movers; we try to go above and beyond for our customers. We work hard to build strong relationships and partnerships with our customers. Our president, Tina Kuo, always reminds us that taking care of the customer is priority one. Giving good service and selling a great quality product.”

As Genstar Technologies embarks on its next 55 years, the beliefs in loyalty, respect and commitment remain as strong as ever. Says Meyers, “Besides being good company values, we think that equates to good business and good growth opportunity for Genstar Technologies.”

Veite Cryogenic Equipment and Service, Inc.

Supplier

Veite Cryogenic Equipment and Service, Inc. was founded in 1969 by Harry and Jim Veite. The company, formerly known as Cryogenic Equipment and Service, serves the U.S., Mexico and Canada from its 14,000 sq. ft. facility in North Ridgeville, Ohio.

In 1969, distributors would typically lease fill plant equipment from their gas suppliers. Because of this, there was no incentive to upgrade equipment and no competitive element to gas pricing. The Veite brothers demonstrated to distributors how to increase profits by installing modern filling systems and the benefits that came from owning their own equipment rather than leasing it.

That commitment to quality and efficiency has driven the company for more than half a century, as Veite has always operated by the golden rule: to treat employees, customers and suppliers as they would like to be treated.

The Veite family remains heavily involved in the business today, with Jim’s son, Mike Veite, serving as president, and James Harris, Jim’s nephew, serving as vice president. James Harris and Mark Veite, Harry’s son, are head installers and have been designing and installing fill plants for more than 40 years.

Cumulatively, the Veite staff has more than 100 years of experience in the cryogenic and high pressure industrial and medical gas industries.

“The flexibility and knowledge of our staff are our strongest assets,” Jim Veite said upon the company’s 50th Anniversary in 2019, shortly before he passed away in August of that year. “Our customers may work with one technician on a small project, but they know that the entire team is ready to jump on the project, if that’s what it takes to get the job done. We place a lot of confidence and trust in our employees and provide them with extensive training to accommodate the heavy workload.”

Concludes President Mike Veite, “Our entire team is honored to work with GAWDA and continue the family legacy that my father and Uncle started 55 years ago. We look forward to living up to the standard that he set every day and continuing to let our customers experience the Veite Difference each and every day. Thank you to everyone who has made these last 55 years possible, we couldn’t have done it without you.”

Vern Lewis Welding Supply, Inc.

In 1969 Vern Lewis was working as a regional sales rep for Forney Industries. He was sent by Forney to sell to the state of Arizona. However, at the time, Forney was having difficulty securing welding rod, so Vern worked out a deal with Lincoln Electric that allowed Vern and his assistant, Ron Ruch, to sell rod to farmers west of Phoenix, which they did out of the back of Vern’s station wagon. However, around that same time, Forney decided to stop selling direct to consumers, and Vern decided to strike out on his own as a distributor and so Vern Lewis Welding Supply, Inc. was born.

The first Vern Lewis Welding Supply was formed in Avondale, Arizona as a warehouse location, selling Lincoln welding rod and welding equipment to the farmers west of Avondale selling only on the road, with the first retail location opening in 1975. It wasn’t long before there was a demand for oxygen and acetylene from the farmers. And, with that, Vern Lewis had entered the gas business.

Things were going well, and they would only get better when the company brought on John Bone in 1995, who is now the President Vern Lewis. Vern hired his daughter, Stacy Lewis Hayes, in 2004, who is now the CEO. Soon a new management team would arise and take the company to places Vern couldn’t have imagined. This team consisted of, and still does to this day, John Bone, Stacy, the company’s long-term business manager, Veronica Bone, and Vern’s most veteran employee, Carol, who’s been with Vern since the beginning of the company. With this team in place, Vern Lewis Welding Supply grew from just two stores in the valley to the seven retail locations throughout the state of Arizona today.

Today, Vern Lewis has seven locations, plus a distribution center and 94 employees.

Says Stacy Lewis Hayes, “Ten years from now, we see our Senior Management retired, the company being run by our Middle Management (thus becoming the Senior Management), that management team mentoring the next management team and Vern Lewis Welding Supply continuing to be the premier welding supply of choice in Arizona.”

50 Years

Analgesic Services, Inc.

Distributor

Analgesic Services, Inc. was founded by Glen Brown in 1974 as one of his many activities in the healthcare industry. The company was later purchased by Jack Watson, who owned and operated the business until 1991, when Ron Andres purchased the company. Andres remains the major shareholder and CEO of ASI to this day.

ASI was presented to Ron as part of a business portfolio with other businesses and some of the purchasing group was uncomfortable with the “liability” that went along with insuring and operating a “compressed gas/hazmat” company. Where others showed apprehension, Ron saw an opportunity. Ron then appointed Steve Shupe, Geary Guy, and Jason Norman as Vice Presidents and, together, they set their sights on building a business founded on relationships. They believed that there was more value in a handshake than any signature in a contract.

“Through four guys and three trucks, they laid the foundation for what principles and values continue to grow the company today,” says Lisa Blackketter, President.

Ron, Steve, Geary and Jason continued to grow the company and growth began to accelerate in 2007.

In 2007, ASI relocated to its first fill plant in Sacramento

In 2008, the company acquired the medical business of Central Welder Supply in Gilroy, CA

In 2014, the company opened a grass roots operation in Phoenix, AZ

In 2018, it opened a location in Denver, CO

In 2019, it acquired Summit Aire, LLC and opened its first industrial gas application

In 2021, it acquired its first hydrostatic testing and cylinder requalification business in Rancho Cordova, CA

Today, ASI has five locations and more than 55 employees, but it is actively looking to add several new positions before the end of 2024.

“One of our philosophies that drives our growth is that we believe in delivering more than what is expected,” says Blackketter. “We pride ourselves when we get the feedback of ‘going above and beyond,’ because that’s our intention. Our company’s biggest differentiator has long been our focus on medical gas instead of the full scope of the industrial business. This has allowed us to provide clients with superlative services that cater to the specialty and high demands of medical, veterinary and dental professionals. We’re also able to have many rich and mutually beneficial relationships with other local independents and support one another in growth efforts or times of challenge and hope to be more support for their medical divisions as well when they purchase their gas wholesale with us.”

As the company celebrates a half-century of growth and success, it looks forward to continuing its forward trajectory.

Concludes Blackketter, “In ten years from now, we envision a team with empowered players and employee longevity in every department. If we are successful, many of our amazing team members will still be with us, in more senior roles, with more locations, training more team members, and be even more rich in the opportunities and relationships that drive our days. We will remain focused and committed to providing the best services at the best rates, by empowering team members with effective training, tools and experience to help them continue to meet their goals.

Black Stallion (Revco Industries, Inc.)

Supplier

Black Stallion was founded as Revco Industries, Inc. in 1974 by Mitchell Chu. Mitchell was joined by his brother, C. Edward Chu, shortly after the company was founded. In 2017, Steve Hwang was named President of the company, a title he continues to hold to this day, with Ed Chu moving into a role as CEO and Chairman of the Board. At the time of the transition, Chu said, “Steve has made numerous positive contributions and is a respected leader within the organization. With Steve as president, along with our experienced management team, Revco is ready to face all challenges and changes in our current business environment.”

At the same time, Revco decided to move forward with a name change, transitioning from its historic Revco Industries name to its current Black Stallion name. Black Stallion had been the flagship product line for Revco Industries since the company began in 1974 and had become one of the best-known brands in the entire welding industry, so the decision to move the Black Stallion name front and center was a natural one. When the decision was made, the company said, “The DBA name leverages the strength of the Black Stallion product line and aligns the company and product brand identities.”

“Users of our gloves, FR garments, and other products know and trust us as Black Stallion,” said Hwang. “We want to leverage the success of Black Stallion through our entire distribution channel and capitalize on the momentum of the brand. We felt it was a good time to make the name change.”

The company says on its website, “At Black Stallion®, being different is business as usual. From our consistent quality to our expertise in marketing support, our goal is to be the best partner we can be. Our honesty will compel you. Our transparency will surprise you. And our creativity will impress you. Give us a chance and we’ll show how passionate we are about being different.”

Black Stallion has grown into the company it is today on the foundation of two key elements: a singular focus on outstanding customer service and a commitment to dynamic product innovation. That vision will help carry Black Stallion as it embarks on its next 50 years.

County Welding Equipment

Distributor

County Welding Equipment was founded in 1974. The company provides a large variety of welding equipment, industrial gases, medical gases, propane, food & beverage, helium, and ultra-high purity. County provides superior services in a friendly atmosphere. Its high-quality products are delivered with excellent customer support – so you can make the most of your time and its equipment! County Welding Equipment’s commitment, experience, and expertise in welding have established business relationships with customers that last a lifetime.

For 50 years, County Welding Equipment has been family owned and operated, serving the Broward and southern Palm Beach counties, conveniently located near I-95 and the Florida Turnpike.

“With 50 years of industry experience under our belts, we can answer any questions or inquiries quickly and accurately,” the company says. “As a family-owned and operated company, County Welding Equipment develops strong personal relationships with customers by offering customized service and high-quality products and services. Our team has the experience and knowledge to help you find what you need. We offer competitive prices and exceptional products and services.”

Conroe Welding Supply Company

Distributor

Conroe Welding Supply Company was founded by Yvron Simpson in 1974. In 1975, the company was purchased by Marvin Lee. At the time, Conroe had two employees. Marvin continued to grow the company until his nephew, Roy Morton left his position at the Chemetron Corporation as National Sales Manager to come work with his uncle at CWS. As the company continued to grow and thrive, eventually Roy offered to purchase the company from Marvin and continued to grow and cultivate it. Conroe has been in the Morton family ever since. Today, Roy’s son, Ricky, son-in-law, Bryan, and two grandsons, Jared and Ryan, all work for the company.

It hasn’t all been smooth sailing for 50 years, however. “In the early 80’s when the oil bust hit, times were tough. Conroe Welding Supply had to diversify to survive,” says Ryan Morton. “We moved from selling just welding supplies to selling products in different business sectors, like medical and beverage gas. Conroe, being one of the fastest-growing cities in the U.S., has definitely been a helping factor over the recent years. Our city and the people in it are what make this place so special.”

Today, Conroe Welding Supply has two locations, along with a sister company, Brazos Valley Welding Supply, which operates in Bryan, Texas. The company has about 45 employees.

“Our company culture has always been one of family,” Ryan says. “Most of our employees have been with our company for 10 to 20 years. Our employee retention tends to be great and that helps us keep a low turnover cost as well. Safety has also become another important factor we have started to focus on. We strive to make safety part of the culture every day. A big thank you to Vito Galiunas for his help in consulting and making safety a priority for CWS.”

He concludes, “Our goal is continued growth. We have just installed a new fill plant in Bryan to take some pressure off of our main fill plant in Conroe, allowing for continued growth at both locations. We are also currently in the process of building a new state-of-the-art facility on a 6-acre tract located here in Conroe. The 38,000 sq. ft. facility will help us to safely provide our customers with a knowledgeable, reliable, and honest source for their gas needs.”

Oxylance

Supplier

Founded in 1974, Oxylance proudly celebrates its 50th anniversary in 2024. The company’s unwavering mission is to deliver high-quality products and exceptional service to its customers. Current President David Cowart, who joined the company in 1976, has been instrumental in steering Oxylance towards success.

“I knew it would be a challenge, but I was confident that I could turn the company around,” says Cowart.

In 1977, a unique opportunity arose, setting the stage for transformative growth.

With strategic acquisitions, Cowart significantly enhanced the company’s efficiencies. Oxylance relocated from Atlanta to Birmingham, Alabama, and purchased its current headquarters in 2004.

Additionally, Oxylance has a distribution facility in Chicago to better serve its customers.

“Our growth has been predominantly organic,” notes Cowart. “While we have integrated a few smaller companies, the core of our expansion is organic.”

Today, Oxylance boasts nearly 50 dedicated employees across its two locations. The company’s mission is steadfast: to provide top-quality solutions specifically designed for the primary metals and demolition industries.

“We don’t cut corners,” emphasizes Cowart. “We are a forward-thinking company that believes in quality products and excellent service.”

Dustin Cowart, Co-President, highlights the company’s dedication, stating, “Two weeks ago, the president was loading a truck on a Saturday. That level of commitment echoes throughout our company. After hours, during emergencies, we are always ready to go above and beyond for our customers.”

This culture of dedication and excellence has enabled Oxylance to thrive for 50 years. Several employees have been with the company for over three decades, a testament to its positive work environment.

“As I approach the end of my career,” reflects David Cowart, “I’m relying on our younger team members to bring fresh ideas and innovative processes that will enhance both the business and the lives of our employees. I’m excited about the future of Oxylance.”

Dustin Cowart concludes, “Our future will be driven by our customers’ needs. We are committed to investing in research and development to provide the best solutions. We look forward to continuing our growth and being wherever our customers need us in the next decade.”

Oxylance’s commitment to excellence, rigorous quality control, and willingness to exceed customer expectations remain the cornerstones of its success. Here’s to another 50 years of innovation and service!

30 Years

Independent Welding Distributors Cooperative (IWDC)

Supplier

Just over three decades ago, the Independent Welding Distributors Association (I.W.D.A.) formed the Independent Welding Distributors Cooperative (IWDC) and shortly afterward merged with the Key Distribution Group (KDG).

“We had a great starting point to build off of,” stated Frank Kasnick, CEO of IWDC. “Over the last 30 years the co-op has grown significantly as Membership’s combined sales more than tripled. Since formation, we opened an Indianapolis, Indiana distribution center and added a second distribution center in Reno, Nevada to serve Members out west. We built out a gas program and a branded specialty gas initiative, our PurityPlus® program, launched an online university and expanded our Weldmark® brand, to name a few milestones over the years.”

“Like all companies, we must continue to evolve and change with the times. Most recently, our Membership addressed private equity ownership and voted to amend our bylaws to create an Affiliate Membership, allowing companies owned by private equity to participate in our co-op. These companies are former independents who value participating in our purchasing and marketing programs and together with our Regular Members, we all benefit. This change was approved in April 2024, and we have signed on five Affiliate Members with more to come.”

The IWDC is a cooperative formed in 1994, which leverages the strengths of its independent welding distributor Members across North America. IWDC Member companies collectively represent over $4.2B in sales, serving a wide range of industries. The common denominator is that these industries look to them for industrial, specialty, and medical gases as well as related equipment, welding hardgoods, and consumables. End-use customers served by IWDC Members benefit from having the unparalleled expertise of a local Member distributor who has access to national-scale purchasing and marketing programs. You can learn more about IWDC at www.iwdc.coop.