2025 is a banner year for GAWDA, as the association is celebrating its 80th anniversary this year. Each year, in the third quarter issue of Welding & Gases Today, we celebrate our distributor and supplier members who are commemorating milestone anniversaries. These past several years have been turbulent, with companies having to navigate difficult waters to continue to stay in business. But GAWDA members are nothing, if not resilient. With dozens of companies throughout the organization being more than 100 years old, it is a testament to our industry that GAWDA members continue to thrive year after year. Congratulations to the following GAWDA members who are celebrating anniversaries in 2025! If you have an anniversary in 2026 and would like to be featured in this issue next year, please reach out today at [email protected].

50 Years

C & C Oxygen Company

GAWDA Distributor Member

Founded in 1975 in Chattanooga, Tennessee, C & C Oxygen Company has served its community for five decades as a family‑owned provider of industrial, medical, and lab gases along with welding equipment and safety supplies. What began as a small local business has grown into a dependable source for high-quality gases and support services throughout the region.

Over the years, C & C Oxygen has earned customer loyalty by focusing on product excellence and responsive service. The company continues to stock a wide range of industrial and medical gas cylinders, welding accessories, and safety equipment, all backed by the hands‑on care of its knowledgeable team. “We take pride in building strong relationships, offering expert guidance, and providing unmatched support to every customer we serve,” the company says.

As it marks its 50th anniversary, C & C Oxygen remains committed to the values that defined its founding—quality, reliability, and local support. Its longevity is a testament to the trust it has built and its ongoing dedication to serving Chattanooga’s industrial, medical, and welding communities

Chemweld

GAWDA Supplier Member

This year, Chemweld, Inc. proudly celebrates its 50th anniversary—a significant milestone that highlights the company’s five decades of dedicated service, product innovation, and customer-first values in the welding and industrial gases industry.

Founded in 1975 by Garry McKenna, a lifelong contributor to the welding and gas community, Chemweld was born out of a clear and urgent need: a safer, more economical, and environmentally responsible alternative to acetylene. McKenna’s response to this challenge was the development of Chemolene, a high-performance fuel gas that has since become a trusted solution across the metalworking market.

For 50 years, Chemweld has remained committed to delivering Chemolene throughout North America—serving professionals with a product that emphasizes performance, safety, and cost-efficiency.

Today, the company is led by Garry’s daughter, Linda McKenna Smith, who has served as President since his retirement in 2013. She is joined by her sister, Carol Lee Woodley, Operations Manager, who plays a key role in maintaining Chemweld’s daily excellence in logistics, safety, and customer care. Their leadership continues the company’s legacy of integrity, technical knowledge, and service-driven growth.

Also central to Chemweld’s success is Carey Canup, Vice President of Sales, whose contributions over the past six years have been instrumental in driving the company’s remarkable growth. His strategic vision and commitment to building strong industry relationships have positioned Chemweld for continued expansion in an increasingly competitive marketplace.

“As we celebrate this milestone, we’re incredibly grateful to our loyal customers, partners, and employees,” said Linda McKenna Smith. “Our success is rooted in the trust our industry has placed in us—and we look forward to building on that trust for the next 50 years.”

With a legacy of innovation and a future focused on excellence, Chemweld, Inc. remains a leading force in fuel gas technology for the welding and gases industry.

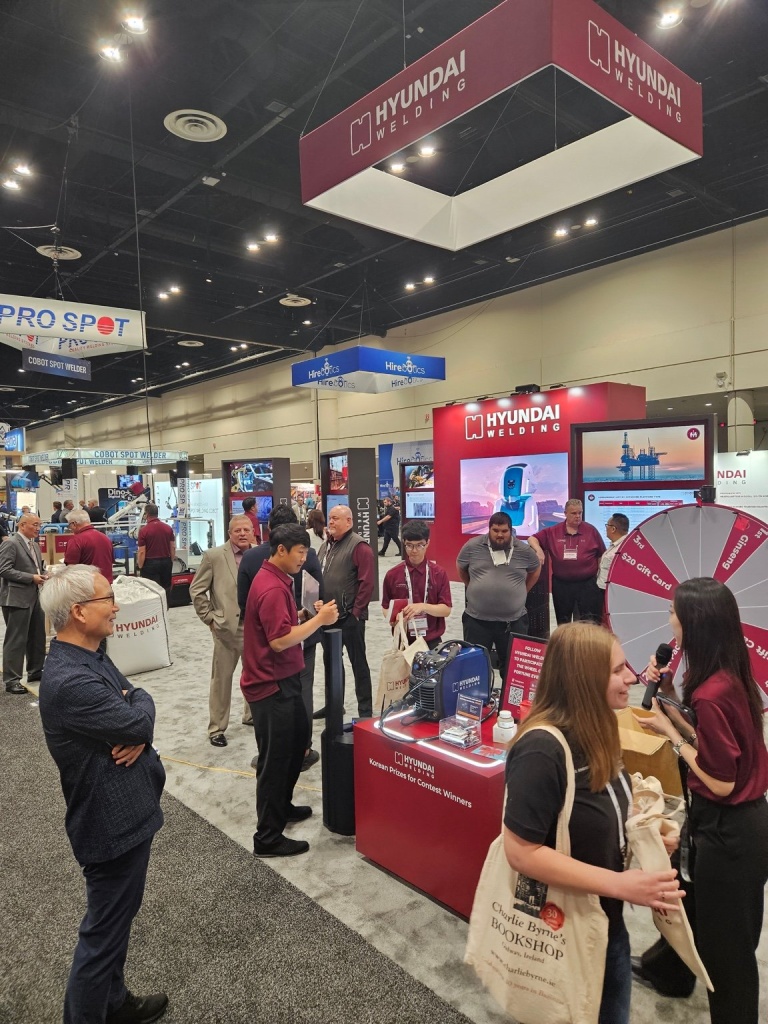

Hyundai Welding Products, Inc.

GAWDA Distributor Member

Hyundai Welding Co., Ltd. began in 1975 as Seohan Development Co., Ltd. in South Korea. In the late 1970s, they kicked off SAW wire and flux production at the Pohang plant, thanks to a technical collaboration with ESAB. By 1987, the company had rebranded to Hyundai Welding Co., Ltd. and in 1989, it set foot in Japan, beginning its global expansion into markets including the U.S., China, Vietnam, Germany, Russia, and Turkey.

Innovation has always been part of the DNA. In 1997, Hyundai Welding built an R&D center that was officially recognized as the Pohang R&D Center in 1999. Over the years, research efforts have led to breakthroughs in welding consumables—such as stick electrodes, SAW materials, solid wire, flux-cored, and TIG—but also in welding equipment like digital inverter welders and eco-friendly Ballast Water Treatment Systems (BWTS).

With a network of global subsidiaries and a focus on R&D, Hyundai Welding now serves heavy industries such as shipbuilding, construction, automotive, pipelines, and green energy. The CEO emphasizes that their leadership comes from ongoing investment in talent, innovation, and manufacturing capability. They are committed to supporting customers worldwide with tailored welding materials and digital tools.

For 50 years, Hyundai Welding has stayed true to its roots—blending customer-focused research, technical leadership, and global reach to meet the evolving needs of industry.

Salem Welding & Supply Co.

GAWDA Distributor Member

Since 1975, Salem Welding & Supply Co. has operated as a family-owned business in Salem, Ohio. Founded by Frederick Baker Sr., his wife Ann Baker, and their son Frederick Baker Jr., the company began as a welding supply and service shop and steadily expanded into advanced metal fabrication.

By 2010, the next generation stepped in when Thomas Baker joined the company. His involvement brought an increased focus on technology and growth, helping modernize operations and improve capabilities across machining, fitting, and welding.

Today, Salem Welding & Supply is known for producing precision weldments handled entirely in-house by certified welders and experienced fitters. The company’s scope of services includes CNC plasma and oxy-fuel cutting, material handling systems, rolling, forming, and machining, all tailored to industries such as metals, telecommunications, plastics, mining, and heavy equipment.

In addition to its custom fabrication work, the company has maintained its legacy as a trusted local welding supplier. Its hands-on approach, customer-first mindset, and regional pride have helped build lasting partnerships with everyone from major manufacturers to local businesses.

Now in its 50th year, Salem Welding & Supply Co. continues to operate on the values it was founded on—skilled craftsmanship, honest work, and commitment to community. The company remains focused on delivering high-quality service and dependable solutions to customers throughout the region.

Steiner Industries

Since 1975, Steiner Industries has built its reputation by listening. The company works closely with distributors to understand their needs and deliver practical, reliable safety solutions for industrial professionals.

From its headquarters and warehouse in Chicago, Steiner supplies a wide range of protective apparel and gear. Their product offering is a blend of in-house manufacturing and globally sourced components, carefully selected to meet rigorous quality standards while maintaining competitive pricing. That balance allows Steiner to deliver consistent performance across a wide array of safety and welding products.

Steiner emphasizes service as much as product. Their customer support team is known for being knowledgeable and responsive, backed by a logistics operation that keeps orders moving fast. Standard orders typically ship within 24 to 48 hours, and custom products within 72. Their centrally located facility supports distributors throughout the U.S. and around the world.

What sets Steiner apart is a company-wide commitment to partnership. Long-term relationships are built on honesty, ethics, and the shared goal of helping customers grow. That spirit is what has earned Steiner the trust of professionals who depend on reliable protection and prompt service.

In a changing world, Steiner remains focused on providing products and service that work hard and adapt to what customers need. For nearly 50 years, pros have counted on Steiner. And that’s not changing anytime soon.

45 Years

Carbo Tech

GAWDA Supplier Member

Carbo Tech was formed in 1980 by Tom Cope and Bill Waters, two veterans with deep experience in the gas industry. After seven years of prep, they officially entered the CO₂ space in 1987, setting the stage for the company’s long-term success. From the start, they believed they could deliver better solutions by going independent — and that spirit still drives the company today.

Since new ownership took over in 2022, Carbo Tech has embraced a renewed focus on culture and strategy. Employees are treated like family, with an emphasis on respect, communication, and accountability. The company has also expanded its services and entered new market segments to support long-term growth.

With one location and a team of 50, Carbo Tech continues to prioritize what it believes matters most: doing right by its people and customers. That mindset has helped the company build strong relationships with major suppliers and stay at the forefront of innovation in the CO₂ space.

Looking forward, Carbo Tech is focused on bringing more outsourced work in-house and just acquired an additional property adjacent to the current location to support future expansion. While the CO₂ industry hasn’t seen massive change over the years, Carbo Tech is positioning itself to be one of the companies that helps drive change in the future.

To mark the anniversary, the team is celebrating with a company party and a deep sense of gratitude for its people, partners, and loyal customers.

TIMS South Texas

GAWDA Distributor Member

In 1980, Tim Ligocky founded TIMS South Texas with one welding truck and a welding machine. The company has been steadily growing and evolving ever since. Today, the company has five locations, with its headquarters in Uvalde, TX, and branches in Asherton, Eagle Pass, and Laredo, and a soon to be completed fifth store in Pleasanton, and 40 employees.

Like many Texas-based companies, TIMS South Texas was heavily dependent on the oil fields in the early days, before diversifying as it grew. In addition to its founder, Robert Stonecipher, Larry Trulove, and Earl Backor have played key roles in shaping TIMS into the business it is today.

“Customer service has always been important to our culture,” Ligocky says. “Our longevity is a testament to the people we have surrounded ourselves with. Our employees and our business contacts.”

Training has also been a key factor in the company’s growth. Says Ligocky, “The industry is moving faster and faster today, with more technology. There is more training available today, than there used to be. We are trying to take advantage of these trainings. We started out the caveman way, but we are trying to use technology better today.”

Through its 40 years, TIMS has seen its fair share of obstacles, including COVID, supply chain and labor shortages. Through it all, the company continues to grow and evolve.

40 Years

EQUIGAS

GAWDA Supplier Member

In 1985, Antonio Arvelo founded EQUIGAS with a simple but powerful goal: to offer better service and support for the gas industry. After building successful ventures in South America, he was frustrated by the lack of reliability when sourcing essential equipment like pumps and valves. So, he launched a new company with customer service at its core. EQUIGAS, short for Equipment for Gas, was born.

The company quickly found its stride, building propane bobtails and turnkey filling plants. Antonio’s son Rafael joined in 1990, followed by Antonio Jr. in 2000 and Nailyn Arvelo in 2009, each bringing skills that helped expand operations and strengthen the company. In 2024, third-generation family member Nicolas Arvelo came on board, ready to carry the legacy forward.

Today, EQUIGAS operates across multiple regions with nearly 80 employees. Their locations in North Carolina, Florida, California, and South America serve customers throughout the Americas. The company’s culture, deeply rooted in family and accountability, continues to drive its resilience.

What truly sets EQUIGAS apart is its people. Team members like the Kokoszka brothers, third-generation gas professionals, bring unmatched experience to every job. Whether identifying parts from a photo or shipping same-day, the team lives by its promise: “We answer the phone and ship the same day.”

As the industry shifts, EQUIGAS keeps adapting. Investments in automation, AI tools, and ERP systems are helping them move faster and smarter. Eight years into its latest chapter, the company is just getting started, and the next generation is already shaping what’s ahead.

FasTest

GAWDA Supplier Member

FasTest was founded in 1986 with a small lineup of connectors. In 1993, then-President Stan Meisinger saw an opportunity to serve the compressed gas industry by improving plant efficiency. FasTest partnered closely with Airgas to refine its product line, eventually making these connectors a standard across the industry.

The company’s growth has always been customer-driven. Its success in the gas sector comes from close collaboration with customers and a steady stream of product development backed by responsive service. That commitment continues to shape how FasTest supports its partners today.

FasTest’s culture starts with safety. The company takes the wellbeing of its customers and employees seriously, which is why its products are designed to be both robust and safe in operation. It also puts a premium on return on investment, building trust through results.

FasTest is known for more than just its products. Its hands-on engineering support and deep understanding of customer processes help it stand out. The company doesn’t just ship connectors—it becomes part of the customer’s system and stays involved throughout the journey.

With over 90 employees across two locations—Roseville, Minnesota and Shenzhen, China—FasTest also leverages global partners to manufacture components. As the company celebrates this milestone, it remains focused on delivering strong

Midalloy

GAWDA Supplier Member

Midalloy got its start in 1985 with a small warehouse, a lot of energy, and two friends, Dennis Nelson and Brad Brunk, who believed they could build something better in the world of specialty welding alloys. They focused on the hard stuff: stainless, nickel, and corrosion-resistant materials. From the beginning, it was about trust, relationships, and showing up with the right solution.

That same spirit still drives the company today. Midalloy has grown, adding carbon steel, aluminum, and three strategic locations, but never lost sight of what matters most: technical integrity, responsiveness, and deep customer care. “We’ve built this by listening to what customers need and staying laser-focused on being reliable,” says President Randy Young. “That means high-performance materials, reliable traceability, and a team that knows how to solve problems.”

Even as the industry has evolved introducing tighter specifications, increased automation, and demand for advanced alloys; Midalloy stayed ahead, not by chasing trends, but by staying committed to sourcing from trusted DFARS mills and investing in its people. Midalloy remains proudly independent and committed to the values it was built on: technical expertise, serve your customers, and stand by your word.

As they mark 40 years, their commitment is stronger than ever with a focus on the continued pursuit of performance alloys and relentless support.

MPT Industries

GAWDA Supplier Member

MPT Industries got its start in 1985, setting a new standard in lubrication, appearance, and specialty additive technologies. Based in Dover, New Jersey, the company now manufactures solutions that protect and enhance equipment across industries like firearms, marine, welding and gas, aviation, and medical.

Over the years, MPT has introduced flagship products including synthetic lubricants, MIL-OPS1™ gun cleaner, and high-gloss polishes designed to maintain finishes without damage. The company has also expanded its line to meet the needs of industrial clients with formulas that reduce corrosion, resist acid rain, and support heavy-duty stamped metal operations.

Today, MPT supports an array of markets—from high-end marine and motorsports to firearms and industrial gas distributors—through a national OEM and retail network. Notably, MPT was named the “Official Motor Oil” of New Jersey Motorsports Park in 2015, underscoring its strong presence in performance and specialty sectors.

Built on a commitment to quality, innovation, and customer trust, MPT continues to invest in advanced additives and appearance products. Its formulas leverage premium base stocks and precision additives, backed by a money-back guarantee on lubricants, sealants, and additives.

With over 40 years in the business, MPT remains focused on delivering products that help customers reduce maintenance downtime, maintain superior performance, and protect valuable assets. The company continues to build on the solid foundation laid by its founders—and looks forward to supporting evolving needs across markets.

Wire Wizard

GAWDA Supplier Member

Wire Wizard Welding Products, a division of ELCo Enterprises, is celebrating 40 years of innovation in the welding industry. Founded in 1985, the company has grown from a single product into the industry leader of wire delivery, torch products and weld cell support equipment used in manufacturing plants across the globe.

Based in Jackson, Michigan, Wire Wizard has built its reputation around solving real-world challenges in welding operations. The company culture focuses on what it calls “The Core Four,” which guides the Wire Wizard team’s purpose, behavior, product innovation and commitment to customers, community and fellow team members.

The company takes great pride in designing, developing and manufacturing American-made welding products. This gives it a significant advantage over other manufacturers importing products from overseas that are often subject to supply chain delays and tariffs. It also allows greater control over quality and production, giving Wire Wizard the ability to quickly supply high performance products to customers.

Wire Wizard’s support goes beyond equipment. The team frequently works side-by-side with customers, helping install systems, train operators, and troubleshoot applications on site. That hands-on approach has earned the trust of distributors and end-users alike.

As it marks four decades as a family-owned business, Wire Wizard remains committed to its legacy of American innovation as it continues to invest in product development, automation, field support, and is heavily focused on the future.

35 Years

ASM – American Standard Manufacturing

GAWDA Supplier Member

American Standard Manufacturing (ASM) was founded in 1990 by Coleman and Connie Vickary in a modest 6,000-square-foot shop in Lawyersville, New York. From day one, the company’s focus was clear: design rugged, high-quality cabinets and handling equipment for propane and gas cylinders. Their first line of cylinder exchange displays quickly became the go-to solution in the grill cylinder exchange market, a reputation they have built on ever since.

In 1994, ASM expanded into its current 28,000-square-foot facility in Central Bridge, New York to keep pace with rising demand. Over the past 30+ years, the company has earned a reputation for quality, safety, smart design, and fast response—and they’ve led the way with products like forklift cylinder cabinets, high-pressure storage units, and ergonomic cylinder handling equipment.

ASM stands out because of its ability to assemble units for same-day shipping—something most competitors can’t match. Their innovative component design system lets customers customize cabinets on demand and replace parts quickly. The use of aluminum and steel with a durable powder coating gives their products staying power in retail and industrial settings.

Built on the Golden Rule, ASM treats employees and customers with respect and care. Staff and customer feedback often inspires new product ideas, improved safety features or vinyl wrap doors. They also partner with Ray Murray (TEECO) on the West Coast, All Propane and Gardner Marsh to ensure a nationwide service reach.

BTIC America

GAWDA Supplier Member

BTIC America Corporation (BAC) began in 1995 as America Fortune Company in Houston, Texas, importing its first high-pressure gas cylinders from Beijing Tianhai Industry Co., Ltd. (BTIC). Since then, the company has grown into a subsidiary of BTIC and was rebranded in 2014 to reflect its strong connection.

BTIC and BAC together operate seven manufacturing facilities worldwide, supplying a broad range of cylinders including acetylene, CNG, cryogenic, fire-fighting, SCBA, and high-pressure DOT/TC and ISO models. The company also offers services such as neck-ring installation and embossing, valving, painting, and dip-tube installation to meet customer needs.

The company’s mission is simple and direct: deliver advanced gas cylinders at competitive prices with top-tier service, treating customers and partners with integrity and professionalism. Customers rely on BAC for reliable cylinders backed by a commitment to continuous improvement.

As BTIC America marks another milestone, it continues to blend global manufacturing strength with local service capabilities. With a foundation built on quality, fairness, and ongoing innovation, the company remains ready to meet the evolving needs of the gas industry.

US Tank & Cryogenic Equipment, Inc.

US Tank & Cryogenic Equipment, Inc. was founded in 1995 by Jim Brown in Sarasota, Florida. After 24 years in the U.S. Navy and advanced cryogenics training, Jim launched the business in a 1,500-square-foot facility. Since then, the company has grown into a 60,000-square-foot operation known nationwide for cryogenic tank repair and refurbishment.

Now based in Lewisburg, Tennessee, the company remains family-owned and committed to quality and service. Jim’s founding principles of integrity, precision, and hands-on workmanship still guide the team today. Every tank the company services is carefully tested, restored, and delivered with attention to detail that reflects its founder’s legacy.

Jim’s son, Jonathan Brown, played a major role in shaping the company’s evolution. With experience in nearly every department, Jonathan brought a craftsman’s mindset and a leader’s focus. Under his guidance, US Tank expanded its capabilities to include spectrometer testing, vacuum processing, oxygen cleaning, NER testing, painting, and reassembly. His impact is still felt deeply following his passing.

The leadership team, including President Michael Tipper, General Manager BJ Gill, Plant Manager Nick Cheek, and the rest of the knowledgeable staff, continues to honor Jim’s vision. Together with their dedicated crew, they deliver responsive, knowledgeable service for clients across the industrial, beverage, and medical gas markets.

US Tank services both new and refurbished liquid cylinders, bulk tanks, and complete fill stations. With its own fleet of trucks and a centrally located facility, the company serves customers across the U.S. and maintains strong industry relationships through trade events and ongoing support.

25 Years

Astaras

GAWDA Supplier Member

Astaras was founded 25 years ago in Largo, FL, with just three employees. In the twenty-five years since, the company has moved and expanded into a 56,000 sq. ft. building with 50 full-time employees. The company began focusing on private label welding consumables.

“Up to this point in welding history, most replacement parts that were not manufactured by original equipment manufacturers were poorly regarded by professional welders,” says Ed Wilson, Director of Operations with more than 23 years of experience at Astaras. “Astaras changed the industry sentiment, as their replacement parts were sourced from ISO certified IBG Group international companies.”

Today, Astaras is part of the ABICOR GROUP. Worldwide, the companies of the ABICOR GROUP are represented at dozens of ISO-certified production sites and in more than 50 countries. As a group of companies, there are more than 2,200 employees worldwide.

“As providing high quality welding products are table stakes in the industry, Astaras has carved out a significant competitive edge in the welding industry by providing comprehensive marketing services to its private label customers,” says Andy Stawski, Marketing Director. “By offering a range of specialized marketing services, including brand development and research, packaging design, merchandising support, collateral development, photography, and digital marketing support, Astaras stands out in the competitive welding industry.”

Since its founding, Astaras has achieved significant business growth by prioritizing the voice of the customer. This customer-centric approach has been integral to their strategy, enabling them to align product development and expansion efforts with the specific needs and goals of their clients. By actively listening to customer feedback and understanding their requirements, Astaras can tailor its offerings to meet evolving demands.

Astaras kicked off the celebration of its 25th anniversary in April by hosting the ABICOR GROUP’s Board of Directors Meeting for the Americas – with participants attending from Argentina, Brazil, Canada, Germany, and Mexico representing ABICOR BINZEL®, THERMACUT®, Kemper System America, Inc., CANTESCO®, and Maquisol®. A special employee celebration lunch will happen in August, recognizing the significant contributions of the staff during the previous 25 years, with more Q4 events scheduled, including some aligned with the 2025 GAWDA AC in Tampa.

CryoVation

GAWDA Supplier Member

CryoVation began in 2000, founded by Ric Boyd after more than four decades in the industrial and cryogenic gas industry. He brought experience from companies like Galiso and Victor Gas Systems to build a firm focused on custom cryogenic and industrial gas cylinder filling and distribution systems.

The company operates from a 40,000-square-foot facility in Hainesport, New Jersey. The building houses a pump fabrication and repair department, a high-purity laboratory, and a new training center designed to support customers and partners. CryoVation offers everything from design and fabrication to on-site installation and long-term technical support.

CryoVation led the market in developing automated cylinder re-testing and filling systems, pre-fabricated palletized plants, and medical oxygen fill systems. They specialize in filling liquid, industrial, medical, and specialty gases, offering fully turnkey solutions and parts through their CryoShop store.

Driven by innovation, safety, and practicality, CryoVation also partners with distributors nationwide to offer local support and training. Their systems are designed for scalability, reliability, and precision—whether it’s a microbulk installation or a fully automated fill plant.

After more than 25 years, CryoVation continues to grow, still built on founder Ric Boyd’s vision. With its inhouse engineering, training, and lab capabilities, the company remains a trusted partner for custom, highperformance gas filling solutions.

20 Years

Commercial Miscellaneous Sales

GAWDA Distributor Member

In 2005, Louis “Louie” Centofanti launched Commercial Miscellaneous Sales in Uniontown, Pennsylvania, alongside his father after growing up around welding and industrial supply. When Louis graduated college, he saw opportunity in serving a market dominated by major suppliers. As he explains, “In the area we live, we’re dominated by major welding and industrial supply companies… there was an opening for an independent.”

What began with the resale of used welding equipment quickly expanded. CMS acquired the assets of Oliver Bottled Gas and entered the gas business by selling and delivering to commercial customers. Over the next decade, the company built its propane and industrial gas operations at its Uniontown facility. Bulk tanks for oxygen (2011), argon (2013), and CO₂ (2017) were added, followed by nitrogen infrastructure in 2019.

The company joined the Independent Welding Distributors Cooperative to gain purchasing power, shipping major brands including Harris, Victor, Lincoln Electric, ESAB, Thermal Dynamics, Tweco, Stoody, Arcair and Select-Arc, while still maintaining personalized family-led service. CMS is also the only Lincoln Dealer in the area that is also a Lincoln Service Center capable of performing warranty repairs in house.

Today CMS employs delivers welding consumables, gases, and industrial products with its own fleet, and continues to expand its delivery radius. “If we don’t have it, can’t get it or can’t make it… it’s not available,” reflects the company motto.

As it celebrates its 20th anniversary, CMS remains grounded in community, expertise, and the goal to be the local distributor of choice every time.

Rainier Welding Supplies

GAWDA Distributor Member

Twenty years ago, Jeff Michaelson took a leap of faith after nearly three decades in the industry and opened the doors of Rainier Welding Supplies. Backed by a Small Business Administration loan and supplier relationships he had built over the years, he launched the company with the support of his wife, who now works part-time alongside him.

Rainier Welding Supplies has grown steadily thanks to word-of-mouth referrals and a reputation for reliability. “Most of our growth has come from customer recommendations,” Jeff says. “Our team is always looking for ways to better serve our customers.” The company has expanded its product offerings to include more safety gear and shop supplies, staying true to its one-stop-shop philosophy.

Customer service is at the heart of Rainier’s culture. The team takes a hands-on approach. Inside sales staff demo equipment, route drivers help manage inventory, and even the billing department plays a role in accuracy and accountability. “We see service as a partnership,” Jeff explains.

With one location and eight employees, most of whom have been with the company for more than a decade, Rainier Welding Supplies has weathered disruptions from tariffs, COVID, and industry shifts. Jeff credits their smaller size with giving them agility during uncertain times and says employee training has helped them keep up with new technologies.

To mark the milestone, the company is treating its team to a weekend celebration with golf, spa time, and good food. It is the kind of appreciation that has helped keep this tight-knit crew going strong for 20 years.

15 Years

Otodata

GAWDA Supplier Member

Otodata has been advancing tank-level monitoring for more than a decade, bringing accuracy and affordability to fuel dealers around the world. Based in Montréal, the company designs, develops, and manufactures both hardware and software. Their lineup includes award-winning monitors, the Otodata Portal, and the Nee Vo mobile app.

The company’s monitors feature long battery life, rugged waterproof casings, dual-SIM connectivity, GPS tracking, and five-year warranties. Users benefit from precise tank data and optimized delivery routes that can lower operating costs by as much as 30 percent. Customers can also access branded mobile apps that allow them to monitor tank levels, receive alerts, and request service with ease.

Otodata’s equipment works with all read-ready dial tanks and is trusted in more than one million installations. With a U.S.-based manufacturing facility and a dedicated global support team, the company serves customers throughout North America and beyond. Otodata also maintains a strong industry presence through more than 80 trade shows and a growing partner network.

The company’s focus is on making smart tank monitoring more accessible and reliable. By combining accurate technology with user-friendly tools, Otodata helps propane and liquid fuel distributors operate more efficiently and serve customers more effectively. Their goal remains steady: to deliver smart, cost-effective monitoring that meets the evolving needs of the industry.

10 Years

Victory Welding Alloys

GAWDA Supplier Member

Victory Welding Alloys is proud to mark a decade of successful service to the welding industry. Since its founding in late 2015, the company has grown into a trusted filler metal supplier with distribution centers in Charlotte, NC, and Houston, TX. Victory is manned by 16 dedicated employees and a strong network of manufacturers’ reps.

What truly sets Victory apart is the family behind the name. It was Nickie Steele (Co-Owner/VP of Accounting) who first saw the potential of matching the sales and executive expertise of her dad, George Foote (Co-Owner/CEO), with the operational and leadership experience of her husband, retired Army lieutenant colonel Brian Steele (Co-Owner/CFO). Together, the three of them established and have grown Victory into a first-rate filler metals wholesale company. Victory recently welcomed its third-generation family member to the business with the addition of Ms. Isabella Steele leading the charge as Head of Marketing. The team blends George’s 40+ years of industry knowledge, Brian’s military-honed leadership and operational expertise, Nickie’s unwavering commitment to family business values, and Isabella’s creative vision for the future.

Over the past decade, Victory has adapted to the evolving environment by navigating supply chain challenges, labor disruptions, and shifting customer demands. Like any growing organization, Victory has had its share of lessons learned; however, with strategic foresight and a commitment to its founding values, Victory has carved out a niche as a nimble, responsive competitor. Entering its second decade, Victory is positioned for further growth with plans for new distribution centers, the release of a signature, Victory-exclusive product line, and direct investment to increase customer service capacity. With family values at its foundation and innovation in mind, Victory Welding Alloys stands ready for what’s next.

5 Years

Meritus Gas Partners

GAWDA Supplier Member

Meritus Gas Partners was founded five years ago, in December 2020. During the past half-decade, the organization has rapidly become one of the predominant figures in the gases and welding industry, forming a partnership of gases and welding supply distributors across the U.S.

When the organization was founded, Scott Kaltrider (Chairman and CEO) and Rob D’Alessandro (President and COO) surveyed the industry and realized that many organizations had owners that were nearing retirement age and either didn’t have a built-in successor or were looking for a way to transition out of the business without selling to a major.

“This created a vacuum in the industry, because there was no real private equity offering in the U.S. packaged gas business,” said D’Alessandro during a 2021 GAWDA TV interview. “The current trends continue to favor consolidation, and distributor-owners continue to face a litany of challenges, which may lead them to elect to sell their business.”

The “Meritus Model” allowed these companies to sell their business while remaining independent, preserving the brand, team and management styles that made them successful to begin with. Using the resources of private equity, these businesses have been able to reach new heights that may have bene inaccessible before.

“Meritus Gas Partners has a different approach to growing our footprint than most other acquiring companies,” says D’Alessandro. “We are looking for partners to co-invest with us to build the industry’s only national independent gas distributor.”

To date, Meritus has partnered with more than 25 gases and welding distributors and suppliers to build a truly nation-wide brand with more than 90 locations in 19 states, with more continuing to be added every day.