In high-purity, corrosive, and toxic gas services, the design and cleanliness of cylinder valves are not just operational details—they are critical safety determinants. Even a single particle, droplet of moisture, or trace amounts of incompatible material can trigger chain reactions leading to leaks, fires, or explosions. Real-world incidents have demonstrated that inadequate valve design or cleanliness has caused fatalities, equipment destruction, and extended production downtime. As reported by Peng et al., “According to a survey by SEMATECH for silane incident, cylinder valve involved in about 16.3% of the incidents and is the second largest source of equipment involved in silane incident.”

Based on the analysis of these cases, requirements and solutions were defined in order to ensure the safety and efficiency of this type of device. These principles form the basis of KOHDA-Cavagna high-purity valves, manufactured in Japan for Cavagna. These products are able to address these risks through robust design, rigorous material selection, ultra-clean manufacturing and proven field performance.

The complexity of these products also lies in the particular role they play. In fact, cylinder valves are the primary control interface between compressed gases and the systems they supply. However, in many operations, they are the most overlooked component in contamination control. For high-purity, corrosive and toxic gases, even minimal traces of foreign materials – whether particulates, moisture, hydrocarbon residues or incompatible materials – can cause catastrophic failures.

What risks may arise with these cylinder valves?

There are many key risks to consider, the first of which is improper design and cleanliness in the cylinder valve have resulted in catastrophic consequences including explosive fires and fatalities.

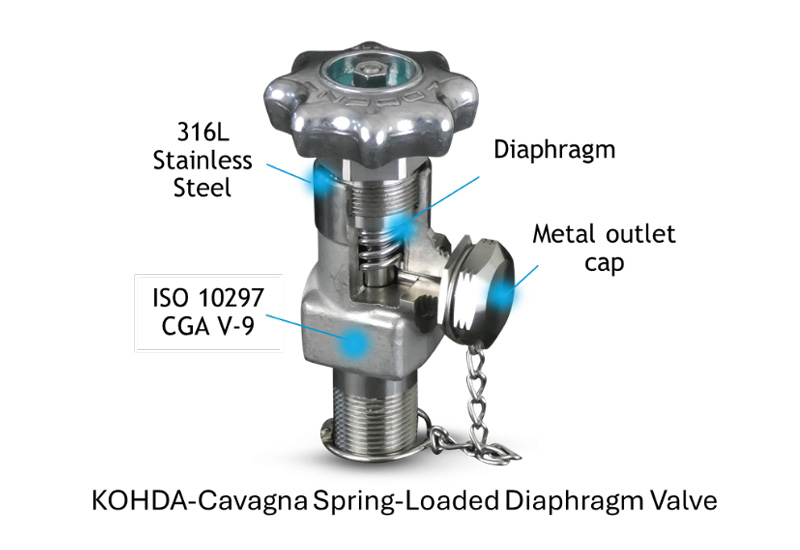

Valve technology has evolved from watertight valves to spring-loaded diaphragm models and, more recently, to tied-diaphragm configurations to meet ultra-high purity and integrity requirements. However, even from a regulatory standpoint, there are no clear guidelines on optimal performance in high-impact gas services.

To overcome this limitation, thanks to decades of direct field experience, KOHDA-Cavagna valves are designed from the ground up to ensure specific gas compatibility and high integrity sealing:

- Gas-specific design verified using ISO 11114-1 and -2 compatibility protocols and internal proprietary field experience.

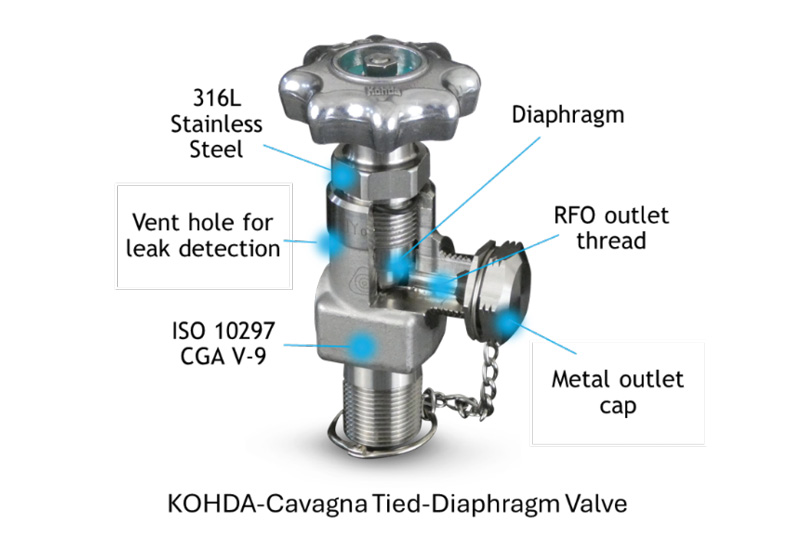

- Spring-Loaded and Tied-diaphragm designs to minimize potential leak paths and particle generation.

- Precision machining and surface finish to reduce particle shedding and moisture retention.

- Reduced gas wetted areas to minimize leak and contamination pathways.

- Qualification beyond minimum standards, using individual helium leak testing exceeding 1×10-7 atm·cc/sec.

Particular attention is also required during the production and pre-use phases, where the condition of the machinery and the type of components used also play an essential role. To meet these requirements, KOHDA-Cavagna valves are individually assembled and tested in clean room conditions to prevent pre-installation contamination and are made of materials that are resistant to corrosion even in the presence of aggressive gases. Each valve is supplied with watertight metal outlet caps to maintain cleanliness until the point of use.

But the risks do not end there. Beyond the production and use phases of the valve, the installation of the valve itself also requires special attention. Assembly to ancillary pressurized equipment should be handled with care, examining the adequacy and compatibility of materials and connections to the intended application.

And once used, their closure and storage are also important. In fact, after use, care must be taken to close the valve without damaging it. The lines must be purged, the outlet sealing caps must be replaced, and the packages must be stored in a dry, clean, ventilated area with adequate valve protection. Plastic dust caps, common in cost-sensitive applications, offer minimal sealing capability.

Here too, KOHDA-Cavagna valves offer significant support thanks to metallic sealing outlet caps compatible with the intended gas and low-torque, precise sealing mechanisms to avoid over-compression damage.

KOHDA-Cavagna high-purity valves, manufactured in Japan, combine proven engineering design, rigorous cleanliness controls, and comprehensive testing to deliver unmatched safety and reliability. Each valve is helium leak tested, individually assembled and tested in cleanroom packaging, and equipped with a metallic sealing outlet cap. With decades of successful deployment in critical gas services, the KOHDA-Cavagna valves stand as a benchmark for mitigating contamination risks and preventing catastrophic failures in specialty gas applications.

Contact: [email protected]

Follow us on LinkedIn: @Cavagna North America Inc.

Peng, D.-J., Chang, Y.-Y., Wu, H.-C., Tsaur, C.-C., & Chen, J.-R. (2008). “Failure analysis of a silane gas cylinder valve: A case study.” Engineering Failure Analysis, 15, 275–280. https://doi.org/10.1016/j.engfailanal.2007.03.004